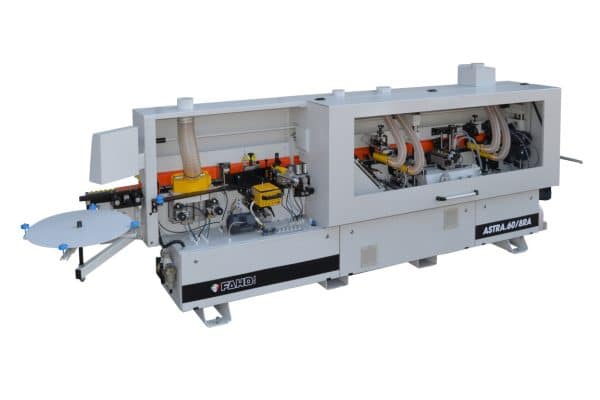

EB-R.EC

Edge Bander for Big and Small Shaped Pieces EB-R.EC

Technical data

| Min – max thickness of the panel | mm 10-60 |

| Edge dim. in rolls min – max | mm 1-3 |

| Min – max height of the edge | mm 18-64 |

| Min radius with concave curve | mm 250 |

| Installed motor power | kW 2,5 |

| Air pressure | bar 7 |

| Weight | kg 600 |

| Overall dimension | mm 2100x1600x1600 |

CE EQUIPMENT

- Turning table unit for large panels

- Nr. 1 dust extraction hood ø 80 mm

OPERATING UNITS

- Gluing unit

- Glue and tape application on big and small shaped panels

- Equipped with glue pot with 1 Kg capacity

- 2 rollers to copy the shape of the piece

- Glue application amount is adjusted via a knob

- Set up of the glue temperature

- Automatic guillotine for coiled material up to 3 mm x 45 mm

- PLC to set the lenght and the cut of the tape (by means of an encoder) for open and closed pieces;

- Laser to make an easy programmation of the cut for closed pieces with no need of measuring the piece

- On/off automatic feeder of the panel

- Raisable working table for small panels

- Utilizes 3 x 500W heating elements with electronic temperature control via thermoregulator

- On/off automatic feeder of the panel

- On/off trimming unit

- 2 rollers to copy the shape of the piece

- Glue and tape application on big and small shaped panels

- Trimming unit

- Trimming unit with 2 motors 0,5 Kw high frequency 15000RPM with up/down and front copiers and manual lever to lift the motors approaching the pieces to be trimmed

- On/off trimming unit

- 2 brazed cutters R=3, Z=6

- Raisable working table for small panels

- Turning table unit for large panels

- Holding arm with vacum table to hold the big panels for edging and trimming

UPON REQUEST

Request a quote

Request a personalized quote for your needs, we will contact you within 48 H!