WHO USES OUR EDGE BANDING MACHINES?

All the machine tools designed and made by FAHDITALIA are in daily use throughout both the carpentry and industrial woodworking sectors.

The furniture and door making industries are, in fact, the main target markets for this product. Robust and compact, it is well designed and has a small footprint.

THE STRENGTHS OF WOOD EDGE BANDING MACHINES

Simple to operate, with extremely short heating times and the ability to adjust operation according to the thickness of the workpiece and the edge required, are a few of the key strengths of FAHDITALIA Edgebanders.

All machines of 100% Italian manufacture and are made according to strict controls in compliance with EC noise and dust emissions legislation.

TYPES OF EDGE BANDING MACHINES FOR WOOD

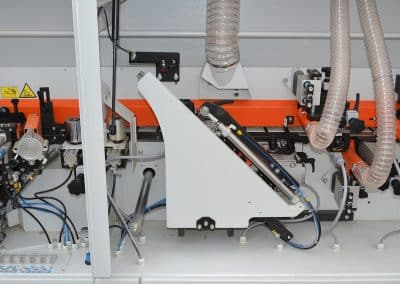

There is a wide choice of different machines available in terms of both size and performance (for pre-glued edges or with glue tank), the machines also allow various processes and are suitable for making adjustments and rounding.

Here is an overview of the various operating units available:

- Pre-Milling unit

- Gluing and edge pressure units

- End-Cutting unit

- Rough-Trimming unit

- Fine-Trimming unit

Positioning of units in the standard machines is manual but it may require management through the control panel. Depending on the thickness and height of the edging used the groups are moved into the working position automatically and by CN.

>> See the full range of Automatic Wood Edge Banding Machines

TECHNICAL FEATURES

- EDGE PROCESSING: solid wood strip edging up to 15mm thick, and rounded edging from 0.4-3mm thick.

- WORKING HEIGHT: working height does not exceed 60mm.

- MIN. PANEL WIDTH: the panel must be a minimum of 80mm wide

- MIN. PANEL LENGTH: the panel must be a minimum of 120mm long

MADE IN ITALY

Our machines are designed entirely in Italy and therefore guarantee a perfect manufacture and widely available parts and service. All machines comply with CE regulations and the required parameters on the issue of noise and dust.

WARRANTY

All FAHDITALIA products are guaranteed against defects in materials and workmanship under normal use and maintenance conditions. The warranty period is 12 months from the date of purchase.

INSTALLATION

The installation service offered by the company is carried out by specialized dealers, present over most of the territory, both nationally and internationally.

Ask for information

If you want a quote, you are looking for a custom machine or you simply need a recommendation for purchase, leave us your contact details together with your message and we will contact you within 48 H!