LEV 110 – 130 P

Wide Belt Sanding Machine LEV 110P – LEV 130P

Technical data

| LEV 110P | LEV 130P | |

| Working width | mm 1100 | mm 1350 |

| Sanding Belts size | mm 1120×2150

on request: mm 1120×2650 |

mm 1370×2150

on request: mm 1370×2650 |

| Max working height | mm 160 | mm 160 |

| 1st sanding belt speed | m/sec 18 | m/sec 18 |

| 2nd sanding belt speed | m/sec 16 | m/sec 16 |

| 3rd sanding belt speed | m/sec 14 | m/sec 14 |

| Motor power | HP 0,75 | HP 0,75 |

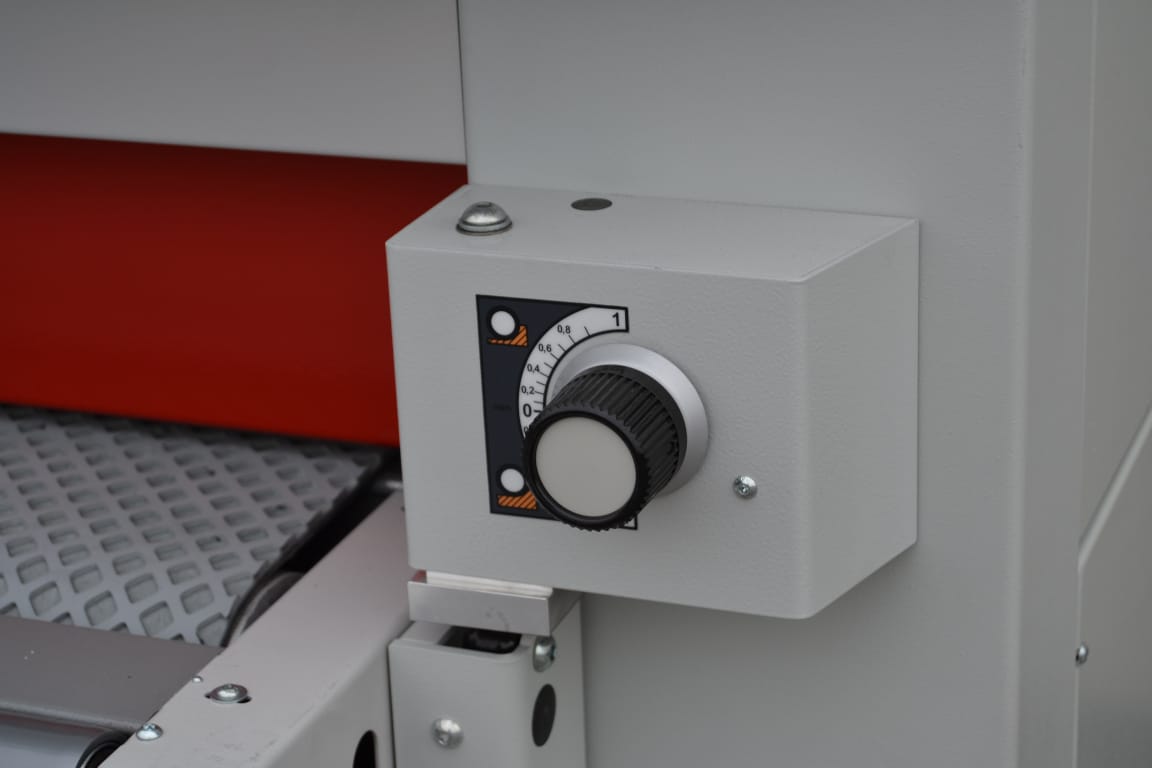

| Feed speed | m/1′ 4-20 | m/1′ 4-20 |

| Working table lifting motor power | HP 0,33 | HP 0,33 |

Available Versions:

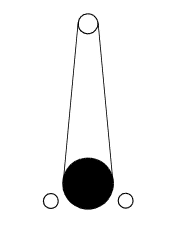

LEV 130P R CE version

- 1 Belt

- 1 Rubber coated roller (85 SH) with helical grooves ø 220 mm

- Motor HP 15

- Variable feed speed motor power HP 0,75

- 1 Dust extraction hood ø 160 mm + 2 ø 80 mm

LEV 130P KRT CE version

- 1 Belt – roller/pad combined unit

- 1 Rubber coated roller (85 SH) with helical grooves ø 180 mm

- Finishing pad 50 mm

- Motor HP 15

- Variable feed speed motor power HP 0,75

- 1 Dust extraction hood ø 160 mm + 2 ø 80 mm

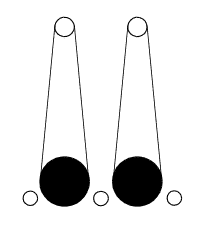

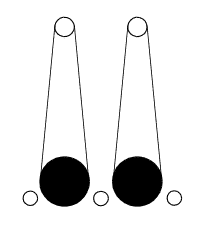

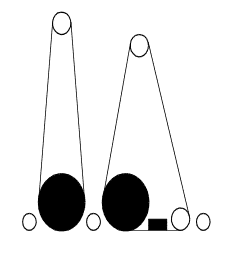

LEV 110P RR CE version

- Belts – roller / roller

- 1st rubber coated roller (85 SH) with helical grooves ø 220 mm

- 2nd rubber coated roller (40 SH) with helical grooves ø 220 mm

- Motor HP 20

- Variable feed speed motor power HP 0,75

- 2 Dust extraction hoods ø 160 mm + 2 ø 80 mm

Extra for version with:

- 1st roller Ø 180 mm and 2nd roller Ø 320 mm

- 1st roller Ø 250 mm and 2nd roller Ø 250 mm

- 1st roller Ø 320 mm and 2nd roller Ø 320 mm

LEV 130P RR CE version

- 2 Belts – roller / roller

- 1st rubber coated roller (85 SH) with helical grooves ø 220 mm

- 2nd rubber coated roller (40 SH) with helical grooves ø 220 mm

- Motor HP 20

- Variable feed speed motor power HP 0,75

- 2 Dust extraction hoods ø 160 mm + 2 ø 80 mm

Extra for version with:

- 1st roller Ø 220 mm and 2nd roller Ø 220 mm

- 1st roller Ø 180 mm and 2nd roller Ø 250 mm

- 1st roller Ø 180 mm and 2nd roller Ø 320 mm

- 1st roller Ø 250 mm and 2nd roller Ø 250 mm

- 1st roller Ø 320 mm and 2nd roller Ø 320 mm

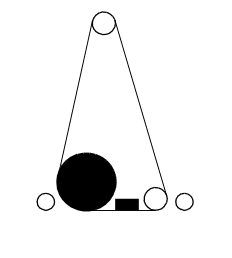

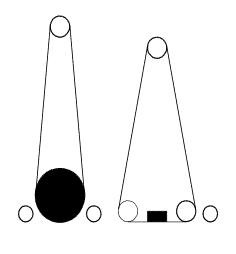

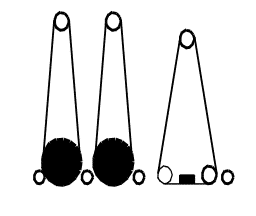

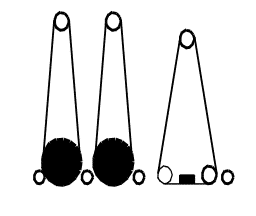

LEV 110P RT CE version

- 2 Belts – roller / pad

- 1st rubber coated roller (85 SH) con with helical grooves ø 220 mm

- 2nd finishing pad 50 mm

- Motor HP 20

- Variable feed speed motor power HP 0,75

- 2 Dust extraction hoods ø 160 mm + 2 ø 80 mm

LEV 130P RT CE version

- 2 Belts – roller / pad

- 1st rubber coated roller (85 SH) con with helical grooves ø 220 mm

- 2nd finishing pad 50 mm

- Motor HP 20

- Variable feed speed motor power HP 0,75

- 2 Dust extraction hoods ø 160 mm + 2 ø 80 mm

Extra for version with 1st roller ø 220 mm

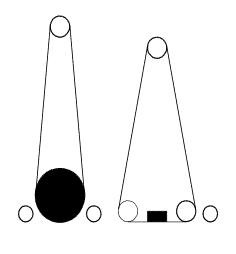

LEV 110P RKRT CE version

- 2 Belts – roller / roller-pad combined unit

- 1st rubber coated roller (85 SH) with helical grooves ø 180 mm

- 2nd combined unit

- Rubber coated roller (40 SH) with helical grooves ø 180 mm

- Finishing pad 50 mm

- Motor HP 20

- Variable feed speed motor power HP 0,75

- 2 Dust extraction hoods ø 160 mm + 2 ø 80 mm

Extra for version with 1st roller ø 320 mm

LEV 130P RKRT CE version

- 2 Belts – roller / roller-pad combined unit

- 1st rubber coated roller (85 SH) with helical grooves ø 180 mm

- 2nd combined unit

- Rubber coated roller (40 SH) with helical grooves ø 180 mm

- Finishing pad 50 mm

- Motor HP 20

- Variable feed speed motor power HP 0,75

- 2 Dust extraction hoods ø 160 mm + 2 ø 80 mm

Extra for version with 1st roller ø 320 mm

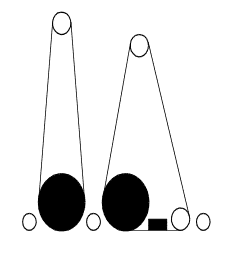

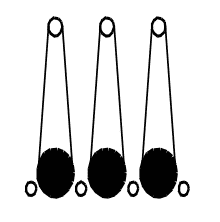

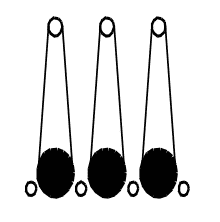

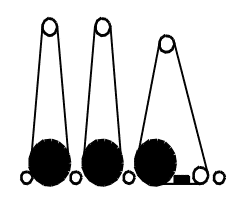

LEV 110P RRR CE version

- 3 Belts – roller / roller / roller

- 1st rubber coated roller (85 SH) with helical grooves ø 220 mm

- 2nd rubber coated roller (hardness on request) with helical grooves ø 220mm

- 3rd rubber coated roller (hardness on request) with helical grooves ø 220mm

- 1st belt motor HP 20

- 2nd/3rd belt motor HP 20

- Variable feed speed motor power HP 0,75

- 3 Dust extraction hoods ø 160 mm + 2 ø 80 mm

LEV 130P RRR CE version

- 3 Belts – roller / roller / roller

- 1st rubber coated roller (85 SH) with helical grooves ø 220 mm

- 2nd rubber coated roller (hardness on request) with helical grooves ø 220mm

- 3rd rubber coated roller (hardness on request) with helical grooves ø 220mm

- 1st belt motor HP 20

- 2nd/3rd belt motor HP 20

- Variable feed speed motor power HP 0,75

- 3 Dust extraction hoods ø 160 mm + 2 ø 80 mm

LEV 110P RRR CE version

- 3 Belts – roller / roller / roller

- 1st rubber coated roller (85 SH) with helical grooves ø 180 mm

- 2nd rubber coated roller (hardness on request) with helical grooves ø 220mm

- 3rd rubber coated roller (hardness on request) with helical grooves ø 320mm

- 1st belt motor HP 20

- 2nd/3rd belt motor HP 20

- Variable feed speed motor power HP 0,75

- 3 Dust extraction hoods ø 160 mm + 2 ø 80 mm

LEV 130P RRR CE version

- 3 Belts – roller / roller / roller

- 1st rubber coated roller (85 SH) with helical grooves ø 180 mm

- 2nd rubber coated roller (hardness on request) with helical grooves ø 220mm

- 3rd rubber coated roller (hardness on request) with helical grooves ø 320mm

- 1st belt motor HP 20

- 2nd/3rd belt motor HP 20

- Variable feed speed motor power HP 0,75

- 3 Dust extraction hoods ø 160 mm + 2 ø 80 mm

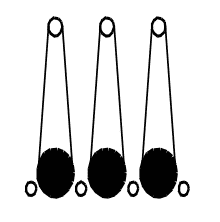

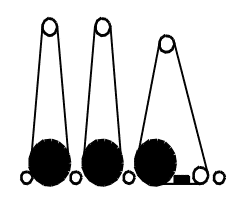

LEV 110P RRT CE version

- 3 Belts – roller / roller / roller

- 1st rubber coated roller (85 SH) with helical grooves ø 180 mm

- 2nd rubber coated roller (40 SH) with helical grooves ø 220 mm

- 3rd finishing pad 50 mm

- 1st belt motor HP 20

- 2nd/3rd belt motor HP 20

- Variable feed speed motor power HP 0,75

- 3 Dust extraction hoods ø 160 mm + 2 ø 80 mm

LEV 130P RRT CE version

- 3 Belts – roller / roller / roller

- 1st rubber coated roller (85 SH) with helical grooves ø 180 mm

- 2nd rubber coated roller (40 SH) with helical grooves ø 220 mm

- 3rd finishing pad 50 mm

- 1st belt motor HP 20

- 2nd/3rd belt motor HP 20

- Variable feed speed motor power HP 0,75

- 3 Dust extraction hoods ø 160 mm + 2 ø 80 mm

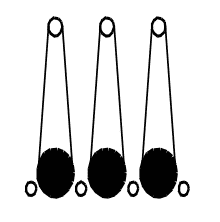

LEV 110P RRKRT CE version

- 3 Belts – roller / roller / roller-pad combined unit

- 1st rubber coated roller (85 SH) with helical grooves ø 180 mm

- 2nd rubber coated roller (hardness on request) with helical grooves ø 180mm

- 3rd combined unit:

- Rubber coated roller (hardness on request) with helical grooves ø 180mm

- Finishing pad 50 mm

- 1st belt motor HP 20

- 2nd/3rd belt motor HP 20

- Variable feed speed motor power HP 0,75

- 3 Dust extraction hoods ø 160 mm + 2 ø 80 mm

LEV 130P RRKRT CE version

- 3 Belts – roller / roller / roller-pad combined unit

- 1st rubber coated roller (85 SH) with helical grooves ø 180 mm

- 2nd rubber coated roller (hardness on request) with helical grooves ø 180mm

- 3rd combined unit:

- Rubber coated roller (hardness on request) with helical grooves ø 180mm

- Finishing pad 50 mm

- 1st belt motor HP 20

- 2nd/3rd belt motor HP 20

- Variable feed speed motor power HP 0,75

- 3 Dust extraction hoods ø 160 mm + 2 ø 80 mm

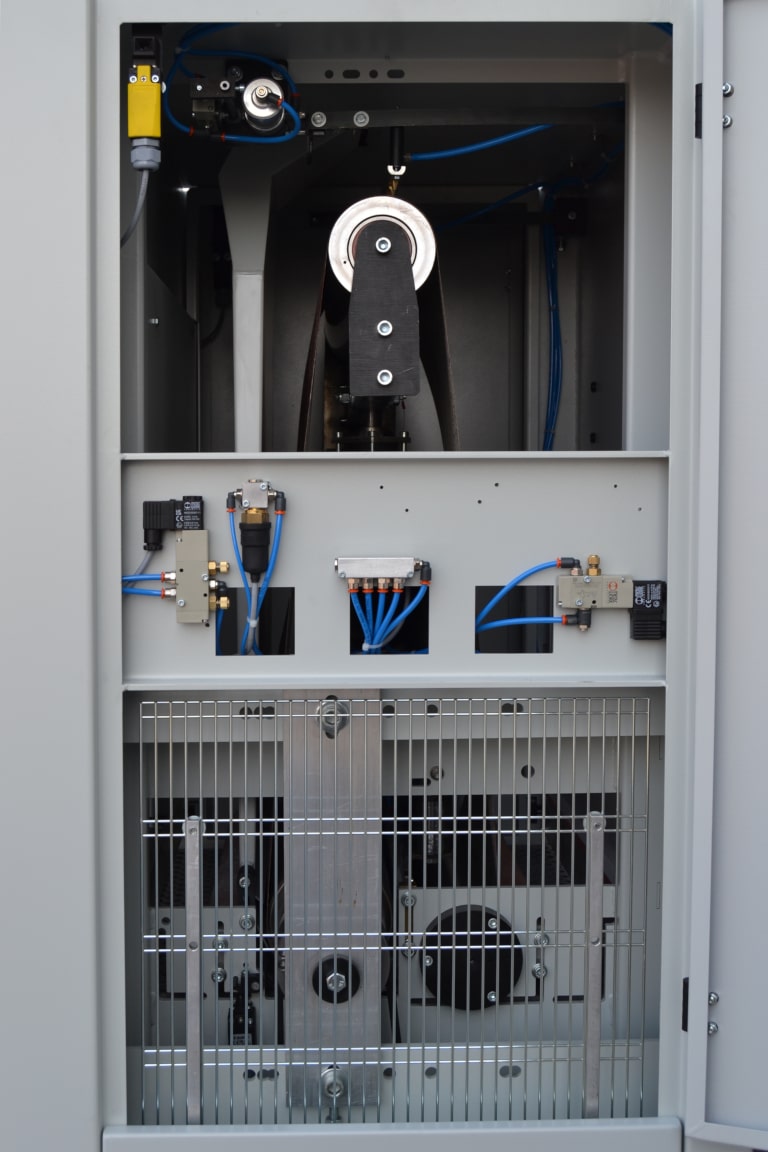

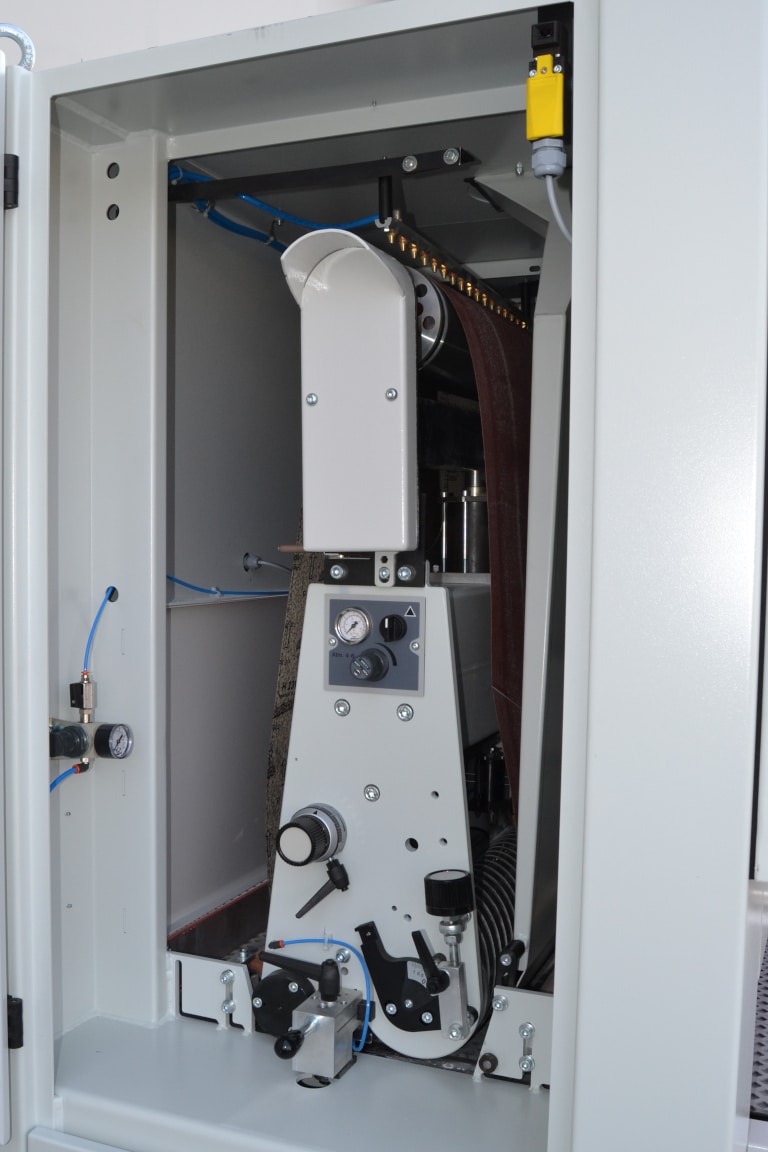

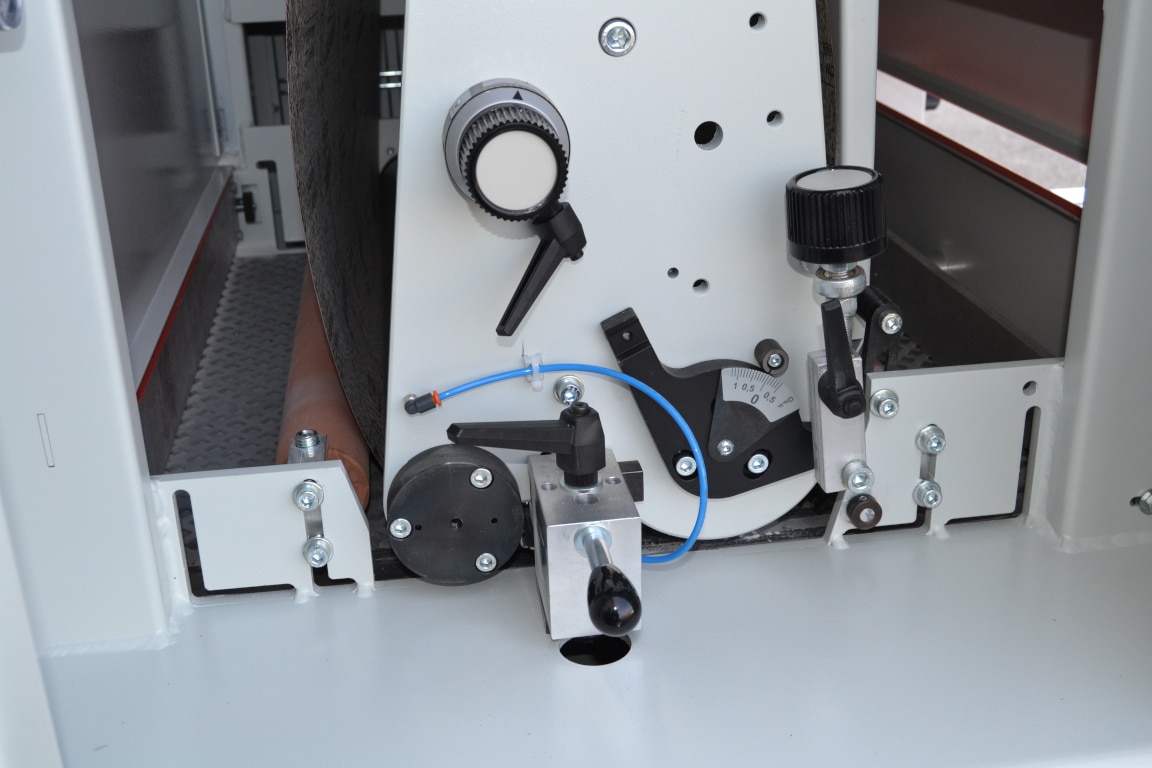

CE EQUIPMENT

- Self centering of the sanding belts by the Eco Gear system our patent

- Belt rotation fast stop brake

- Oscillating tensioning roller

- Rubber coated pressure rollers

- Safety bar

- Electronic digital readout of work piece thickness

- Nr.2 infeed and nr.2 outfeed table rollers

- Automatic table positioning

- Automatic centering of the mat

- Check Control (3 belts version included)

- Automatic rollers exclusion

UPON REQUEST

Request a quote

Request a personalized quote for your needs, we will contact you within 48 H!