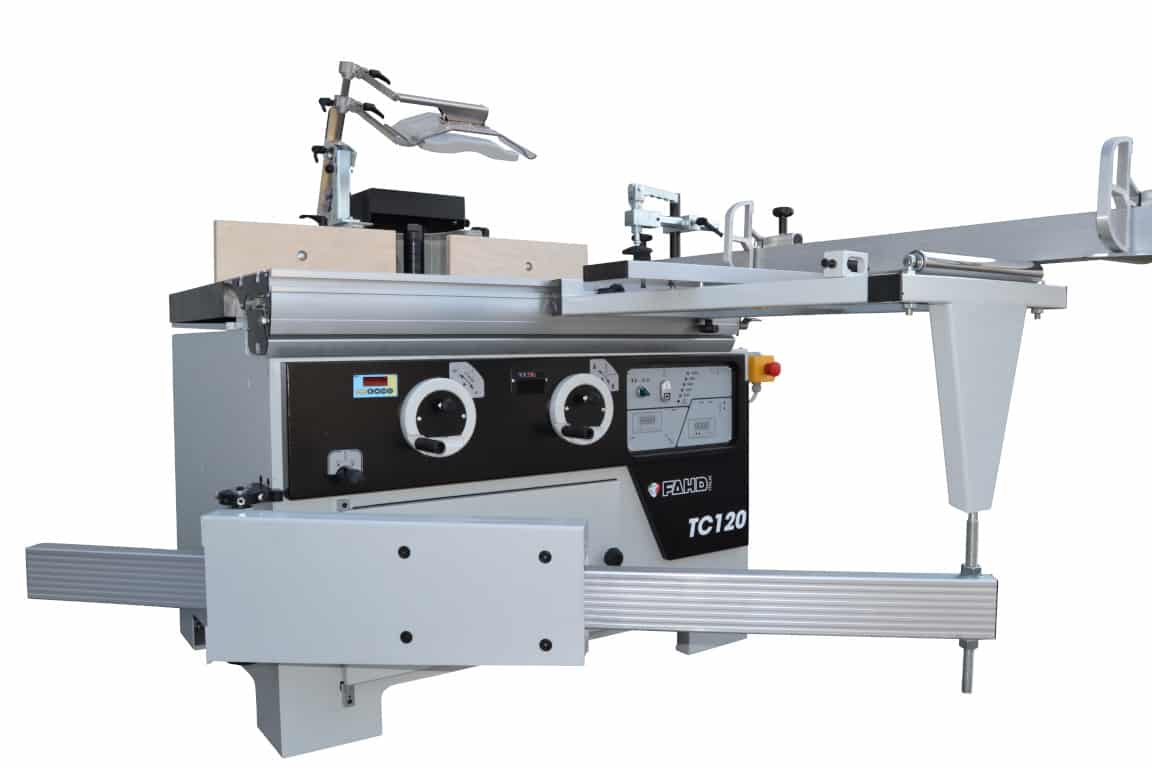

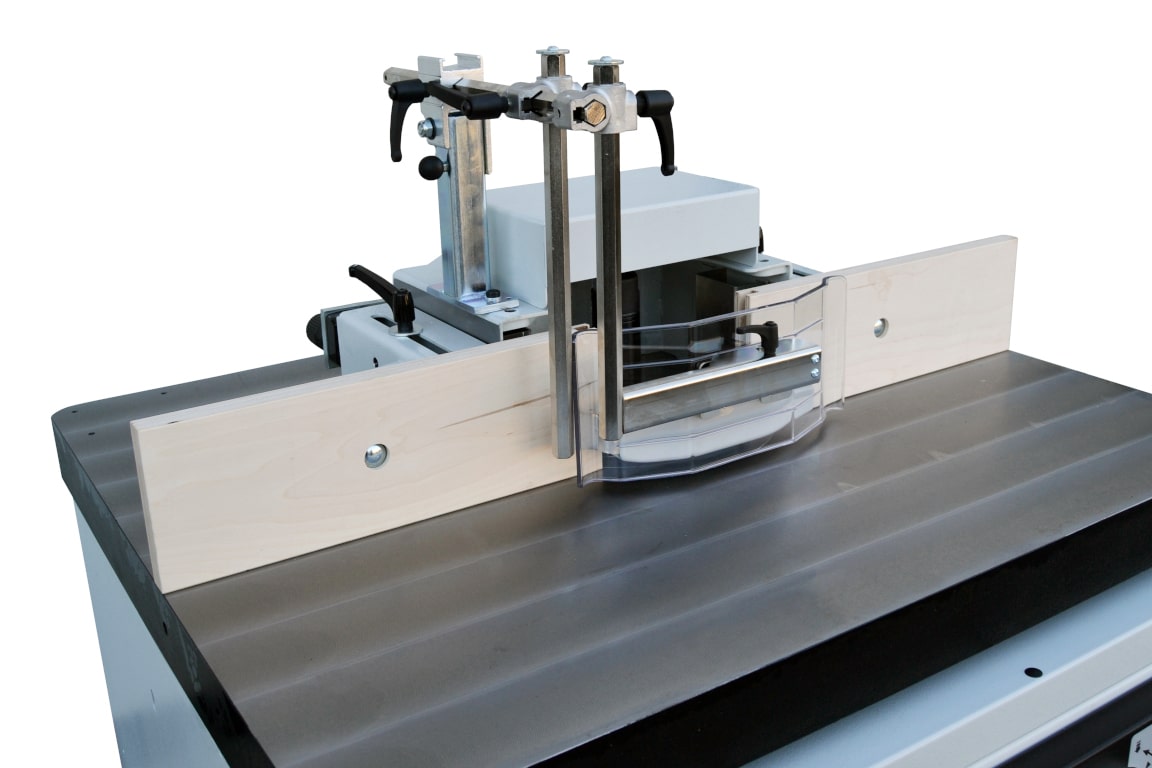

TC 120

Spindle Moulder with Carriage TC 120

Technical data

| Fixed working table dimensions | mm 640×1100 |

| Aluminium sliding table dimensions | mm 360×1100 |

| Available spindle diameters | mm 30-35-40-50 |

| Max table opening | mm 350×80 |

| Vertical stroke (spindle Ø 30-35) | mm 140 |

| Vertical stroke (spindle Ø 40-50) | mm180 |

| Working table height | mm 890 |

| Spindle speed | rpm 2500/4200/6000/8000/10000 |

| Motor power | HP 5,5 |

| Weight | kg 640 |

STANDARD EQUIPMENT

- Spindle hood

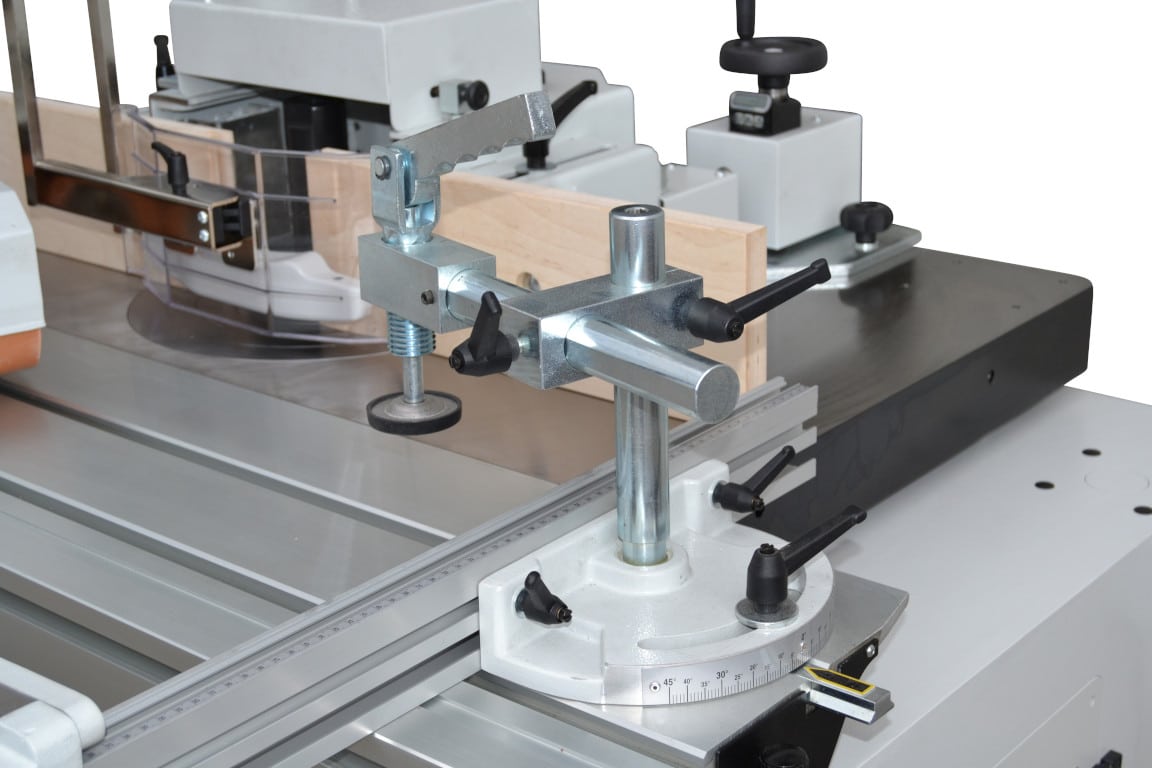

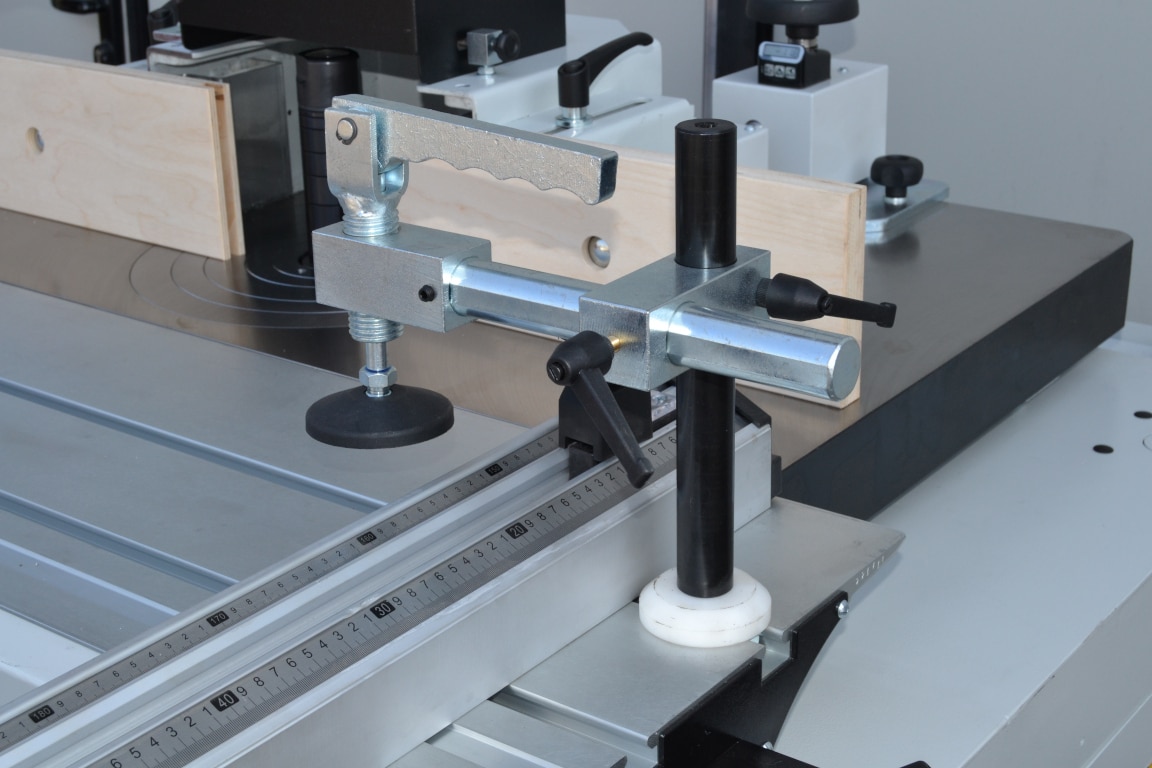

- Angular cutting device

- Eccentric clamp

- 2 dust extraction hoods ( 1 x ø 60 mm, 1 x ø 120 mm)

- Manual star/delta switch

CE EQUIPMENT

- Spindle hood

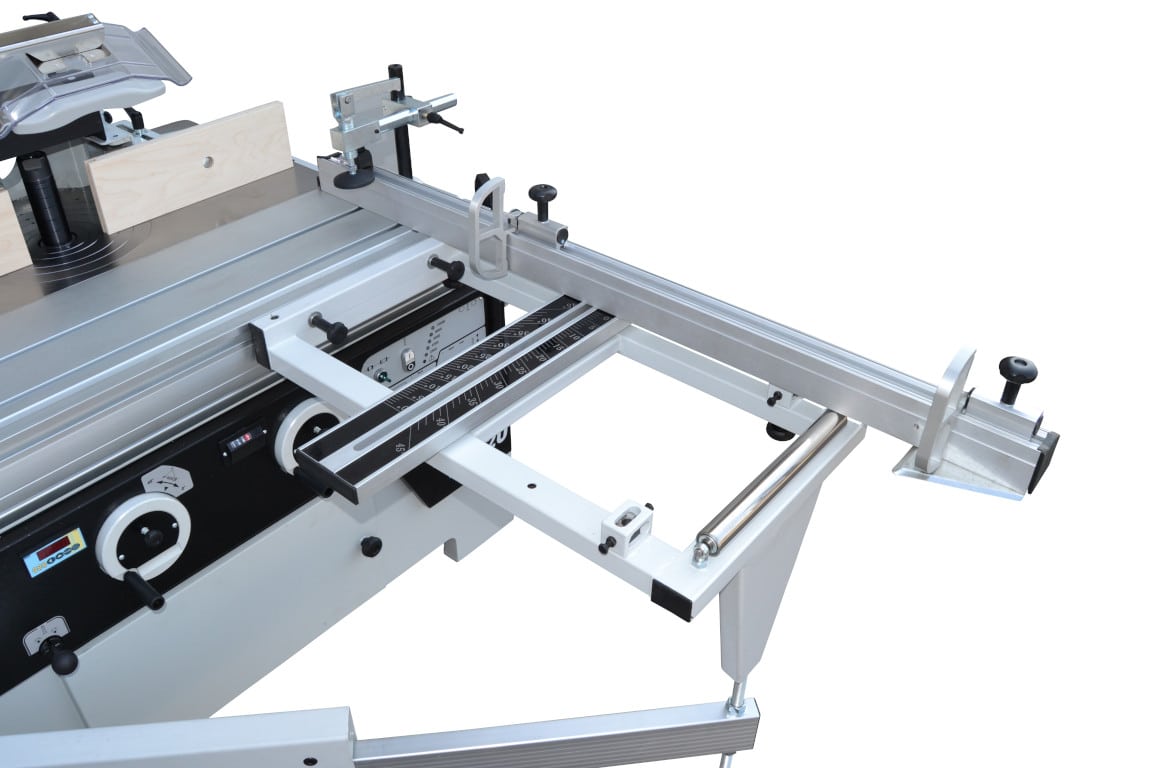

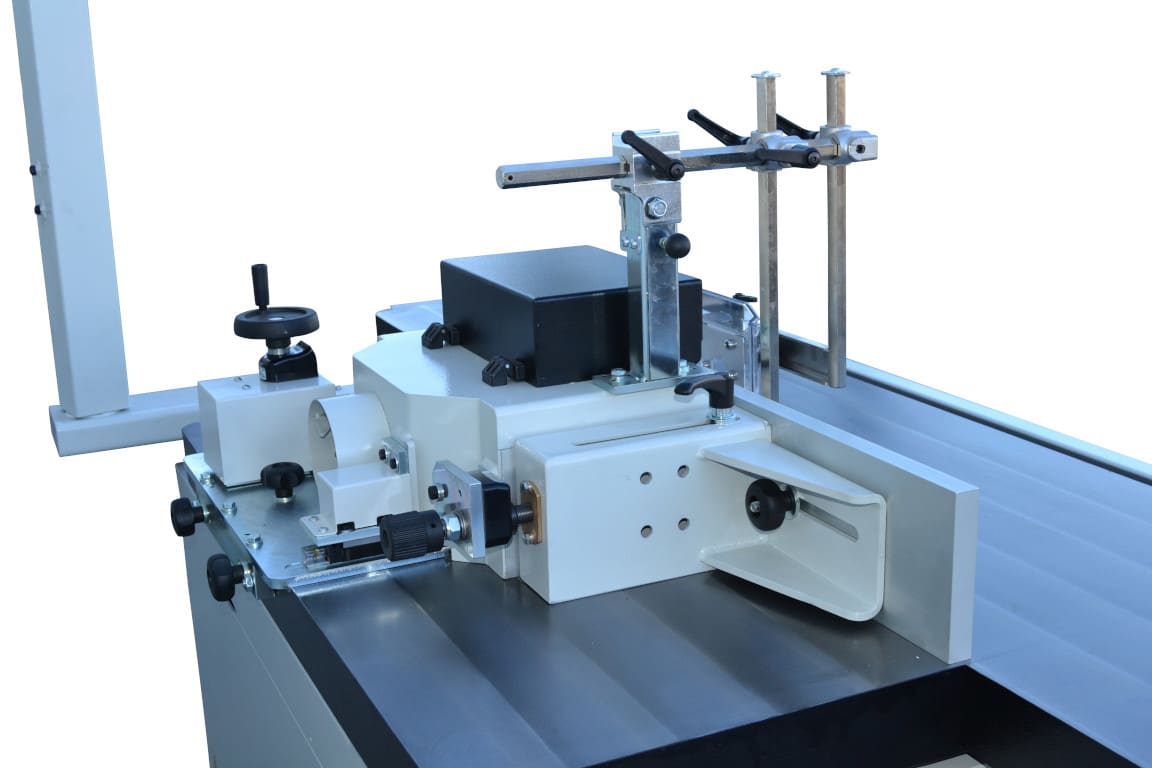

- Fence with linear handling through hand-wheels and displacements displayed by decimal mechanical numerators. Scrolling on linear ball recirculation guides

- 2 dust extraction hoods ( 1 x ø 80 mm, 1 x ø 120 mm)

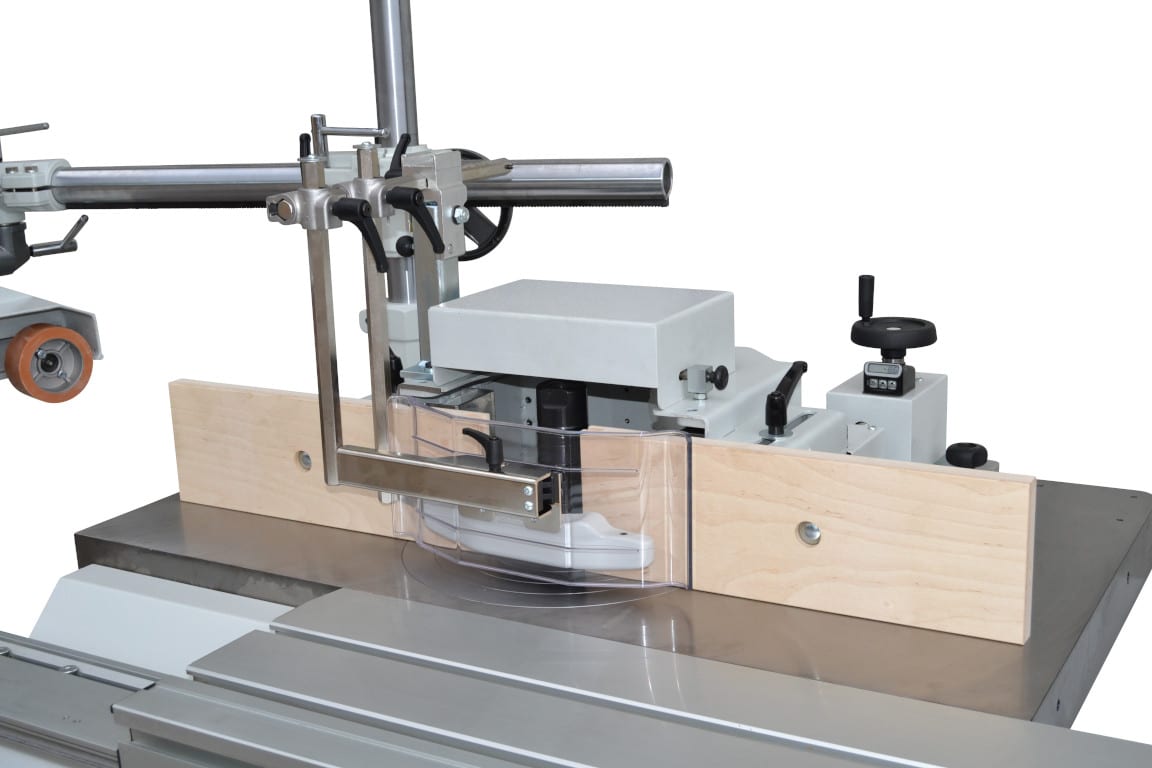

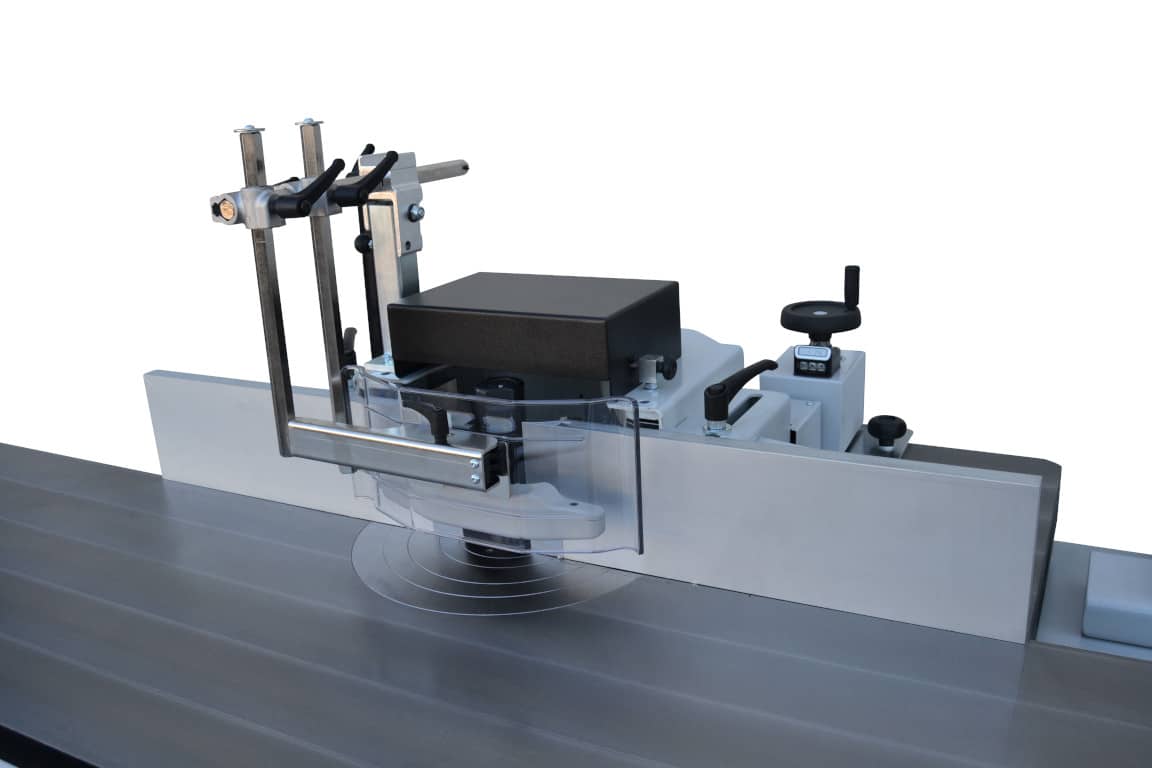

- Profiling spindle hood

- Rounding spindle hood

- Automatic star/delta switch

- Self-braking motor

- Spindle upstroke readout

- Readout for spindle speed

- Spindle protections CE type

- Electrical configuration for feeder

UPON REQUEST

Request a quote

Request a personalized quote for your needs, we will contact you within 48 H!