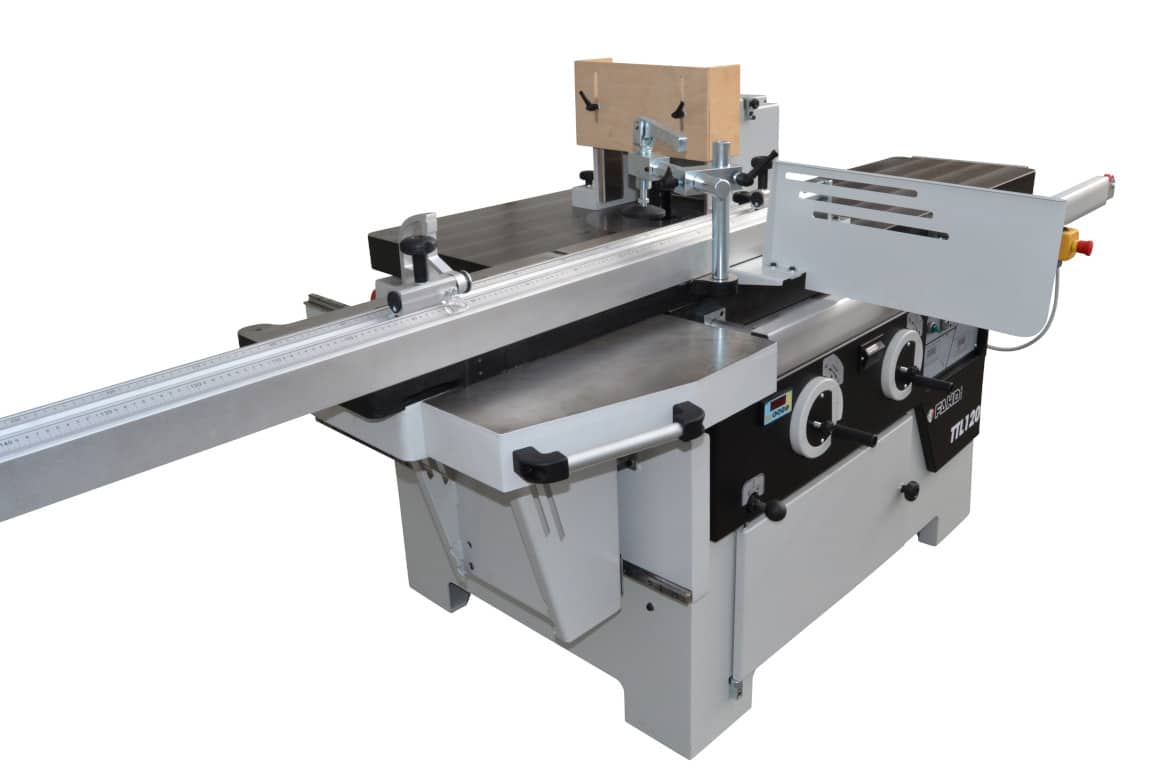

TT 120 – TTL 120

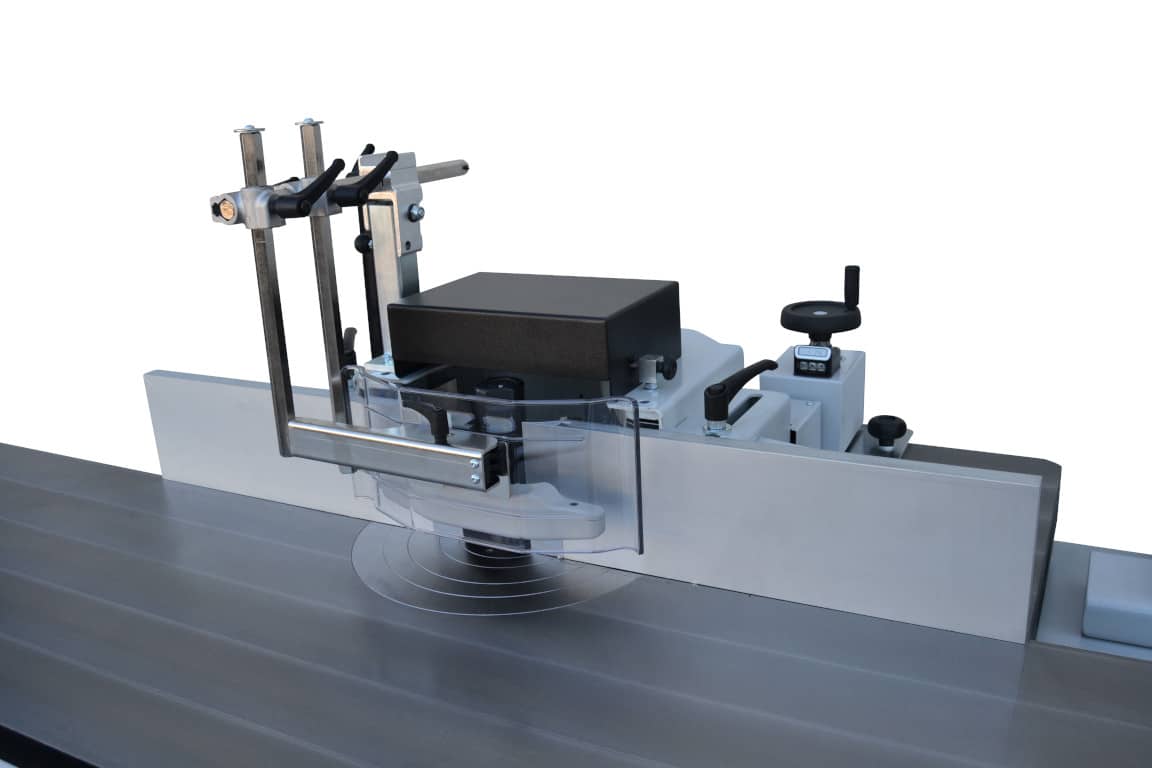

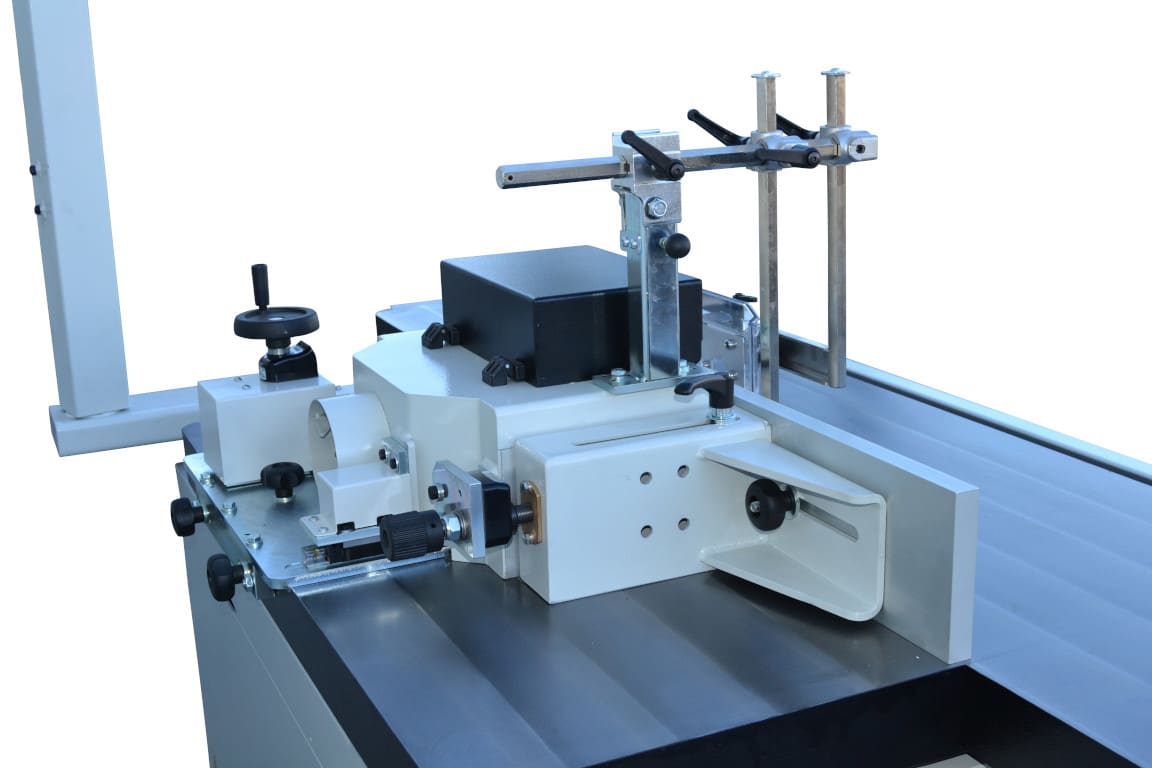

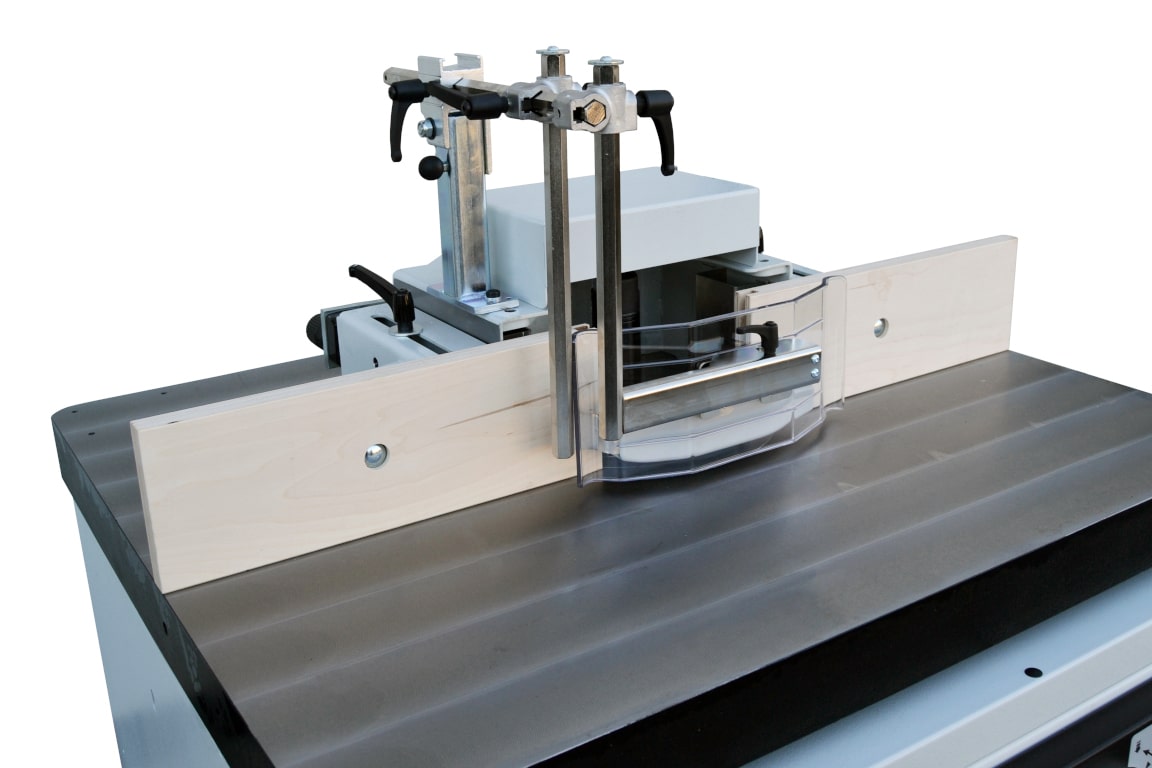

Tenoning Spindle Moulder TT 120 – TTL 120

Technical data

| TT 120 | TTL 120 | |

| Working table dimensions | mm 745×1100 | mm 920×1700 |

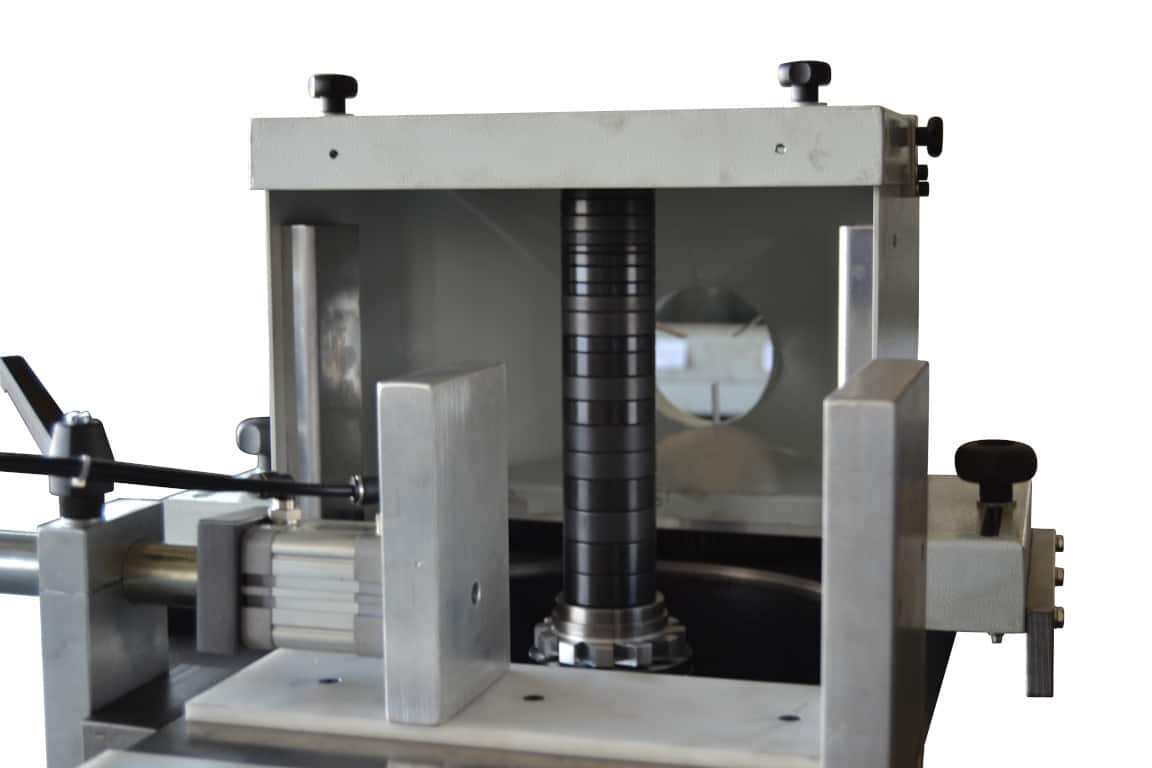

| Available spindle diameters | mm 30-35-40-50 | mm 30-35-40-50 |

| Max table opening | mm 350×80 | mm 350×80 |

| Vertical stroke (spindle Ø 30-35) | mm 140 | mm 140 |

| Vertical stroke (spindle Ø 40-50) | mm180 | mm180 |

| Working table height | mm 890 | mm 890 |

| Spindle speed | rpm 2500/4200/6000/8000/10000 | rpm 2500/4200/6000/8000/10000 |

| Motor power | HP 7,5 | HP 7,5 |

| Weight | kg 690 | kg 820 |

STANDARD EQUIPMENT

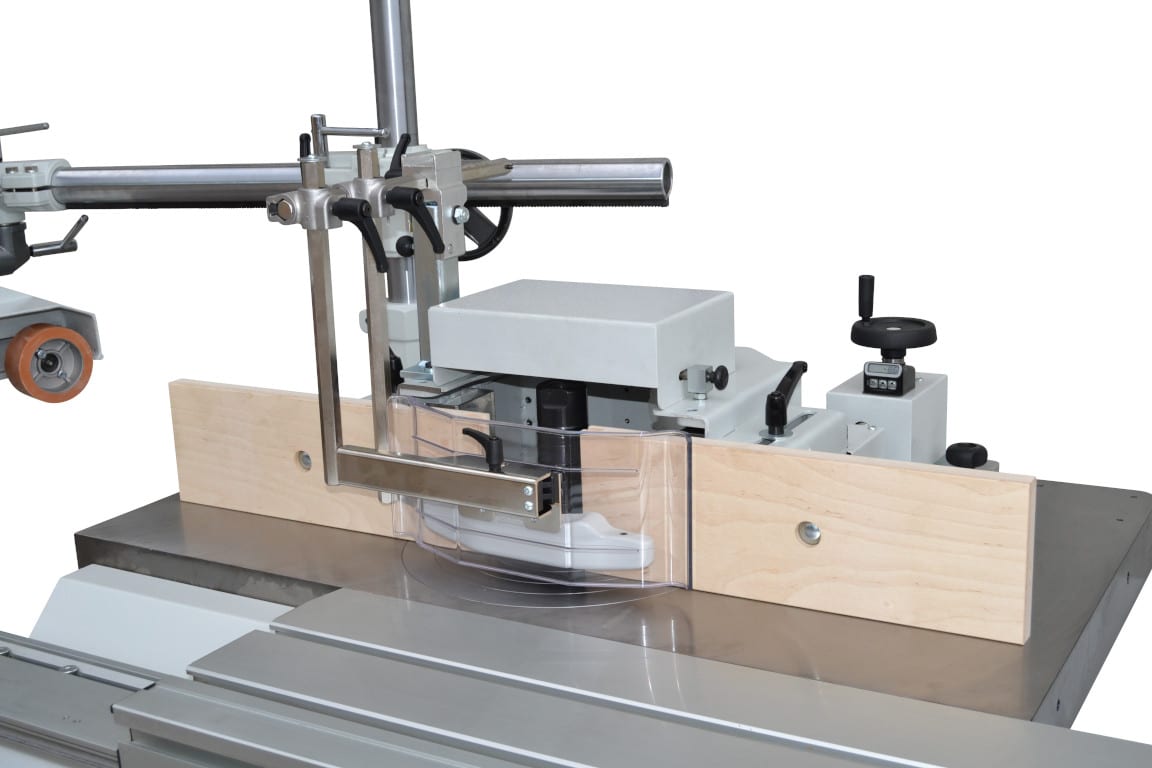

- Profiling spindle hood with dust extraction hood ø 120 mm

- Tenoning spindle hood with dust extraction hood ø 120 mm

- Dust extraction hood on back machine ø 80 mm

- Telescopic fence with 2 stops

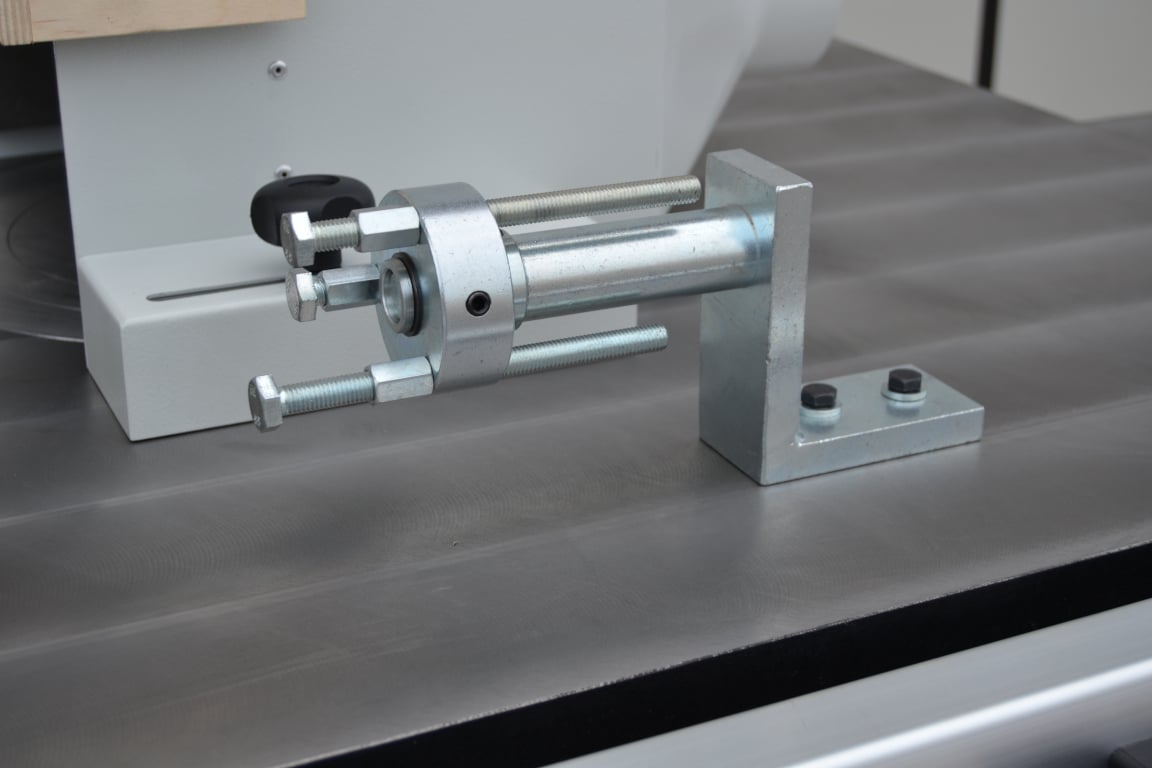

- Eccentric clamp

- Manual star/delta switch

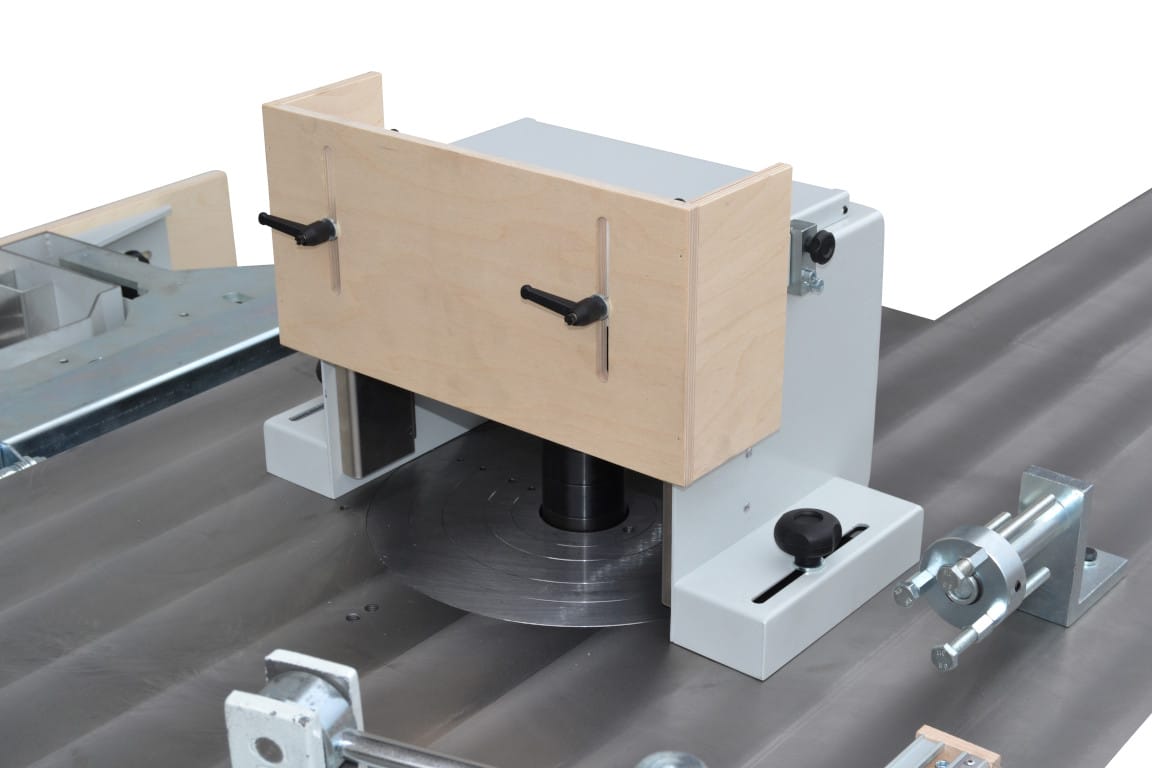

- Revolver for workpiece length reference

- Adjustable frontal bar for big dimensions pieces (for TTL 120)

CE EQUIPMENT

- Profiling spindle hood with dust extraction hood ø 120 mm

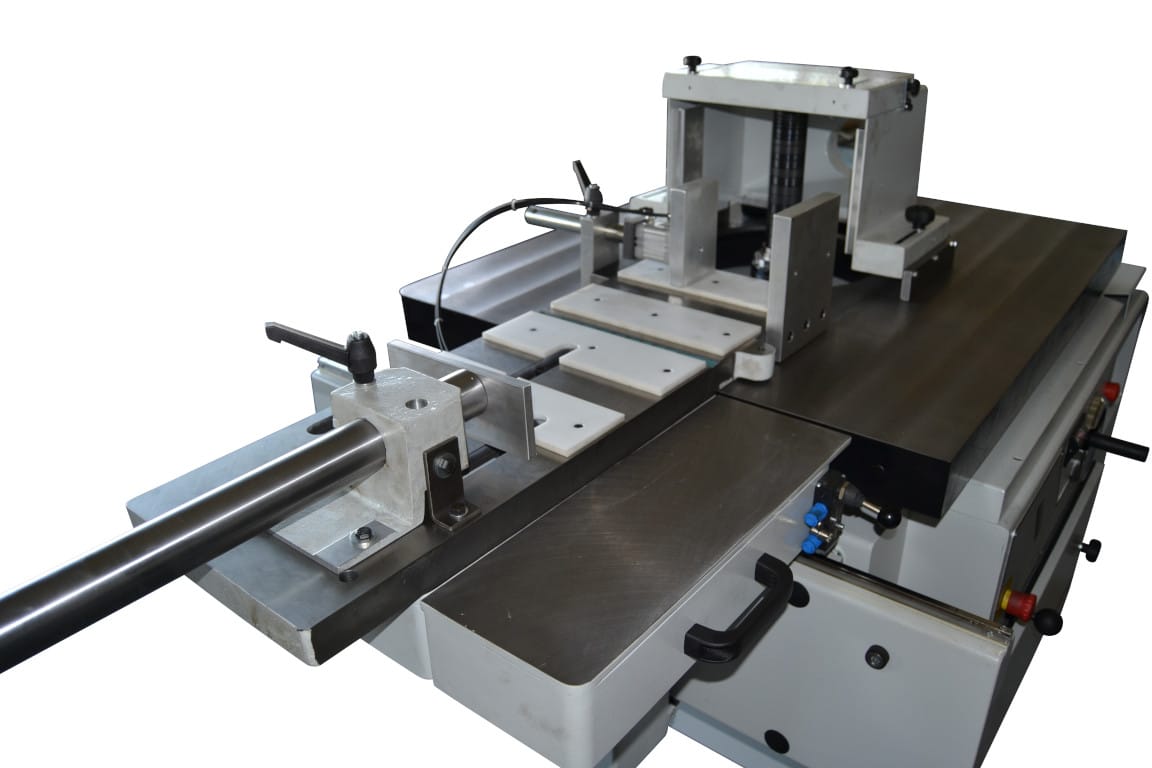

- Fence with linear handling through hand-wheels and displacements displayed by decimal mechanical numerators. Scrolling on linear ball recirculation guides

- Tenoning spindle hood with dust extraction hood ø 120 mm

- Dust extraction hood on back machine ø 80 mm

- Profiling spindle hood

- Rounding spindle hood

- Telescopic fence with 2 stops

- Eccentric clamp

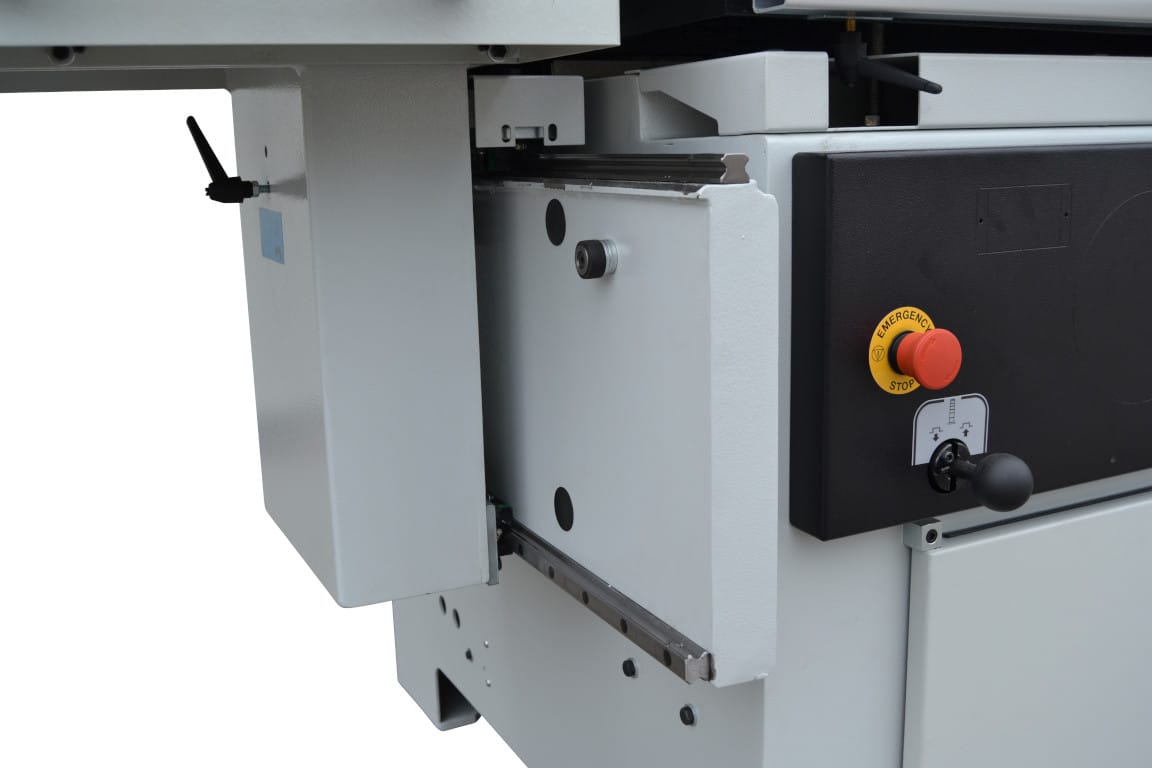

- Automatic star/delta switch

- Self-braking motor

- Spindle upstroke readout

- Readout for spindle speed

- Spindle protections CE type

- Electrical configuration for feeder

- Revolver for workpiece length reference

- Adjustable frontal bar for big dimensions pieces (for TTL 120)

UPON REQUEST

Request a quote

Request a personalized quote for your needs, we will contact you within 48 H!