ASTRA.60/8RA2.CN

CN Automatic Edge Bander with Pre-Milling and Rounding Unitis at 2 Motors ASTRA.60/8RA2.CN

| Pre-milling unit | Gluing unit | End-cutting unit | Edge trimming unit | Rounding unit | Edge scraper unit | Glue scraper unit | Buffing unit |

|

|

|

|

|

|

|

|

Technical data

| Min width of the panel | mm 100 |

| Min length of the panel | mm 120 |

| Min length of the panel with rounding units | mm 120 |

| Max thickness of the panel | mm 60 |

| Min thickness of the panel | mm 10 |

| Edge dim. in rolls min – max | mm 0,4 (min.) – mm 3 (max.) |

| Edge dim. in strips | mm 5 |

| Feed speed | m 1′ 10 |

| Glue pot capacity | lt 2 |

| Installed power | kW 9,6 |

| Air pressure | Bar 7 |

| Weight | kg 1730 |

| Length of the machine | mm 5100 |

CE EQUIPMENT

- Tape roll holder table ø 700 mm

-

Nr.2 tools

-

Conveyor roller for wide panels

-

3 mm thickness roll edge cutter

-

Manual movement of the upper pressure with digital readout

-

Teflon pot

-

Protection booth on all operation units

-

Nr. 2 dust extraction hood ø 110 mm + nr. 2 ø 120 mm

-

Operating units managed by PLC touch screen 10”

-

Operating units managed by PLC positioning by servo-motors

-

Quick release glue pot

OPERATING UNITS

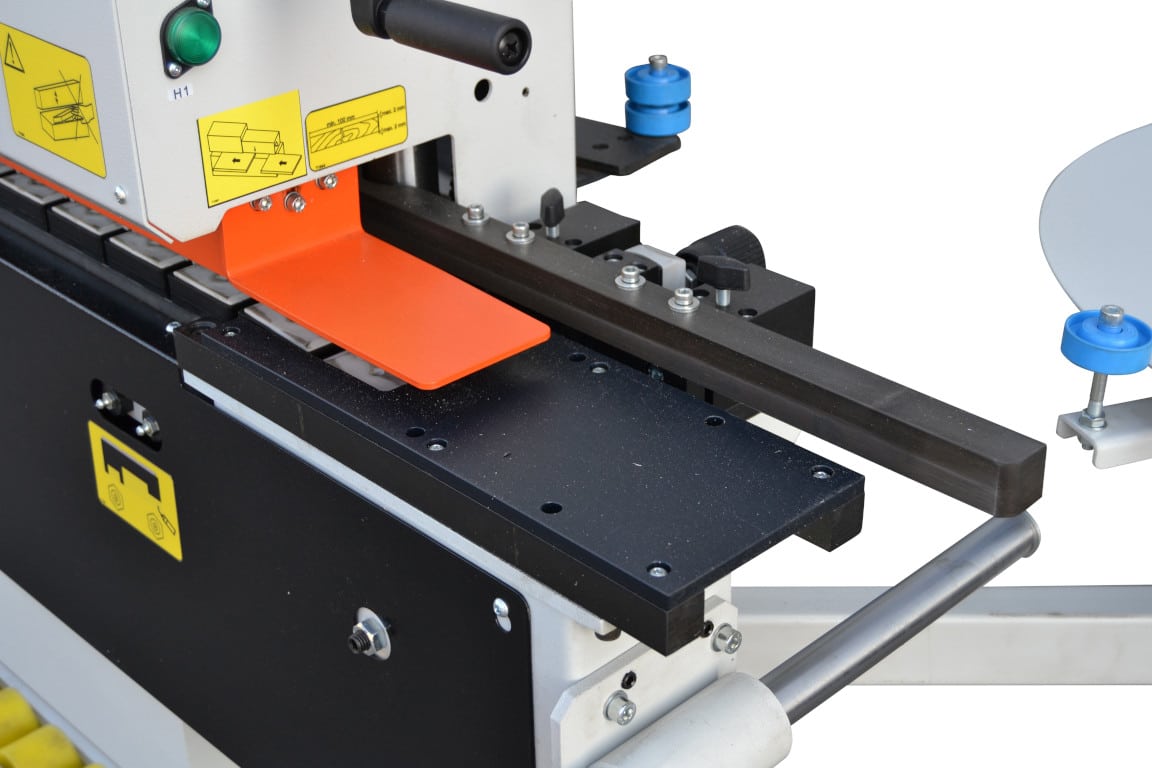

- Powered pressure bar positioning managed by CN

- Powered infeed guide positioning managed by CN

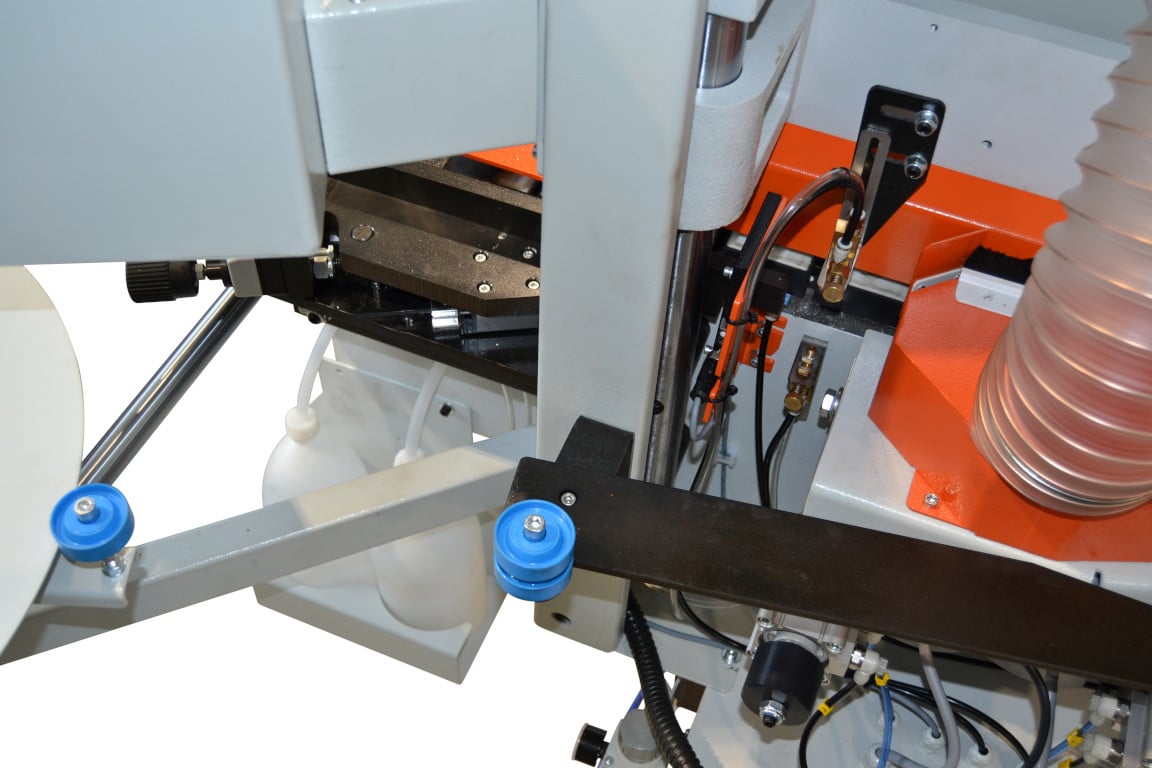

- Anti-adhesive unit

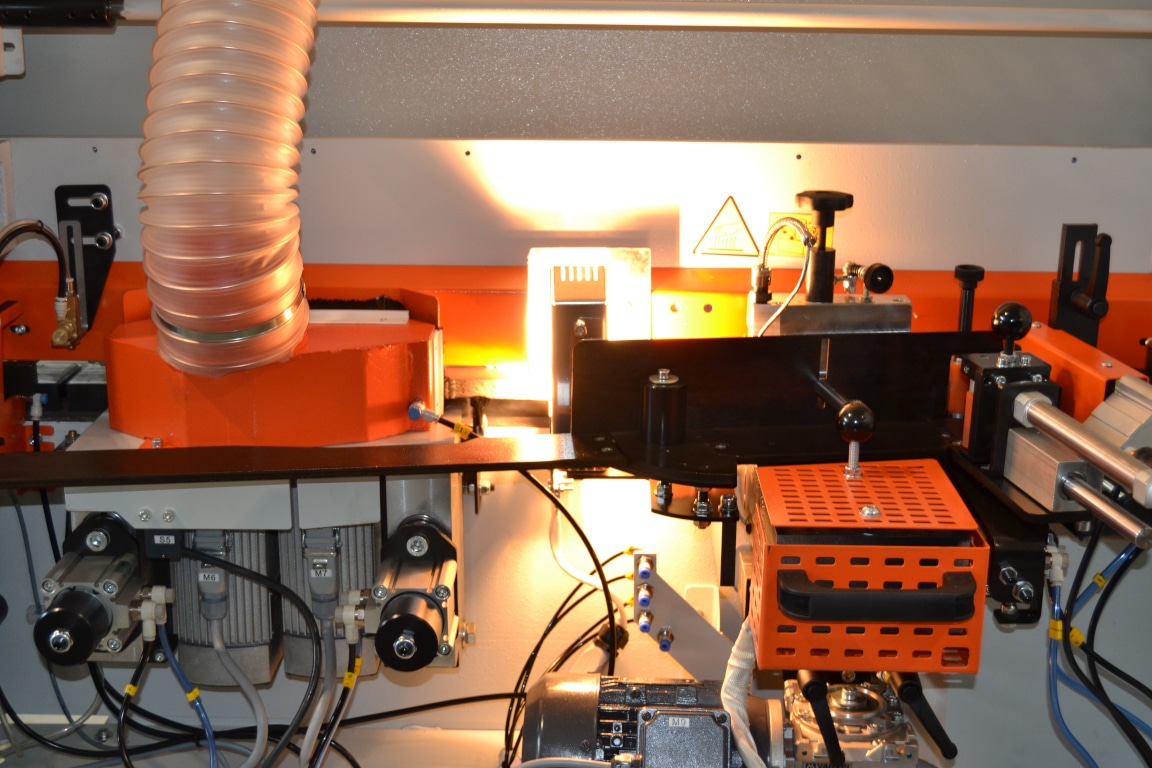

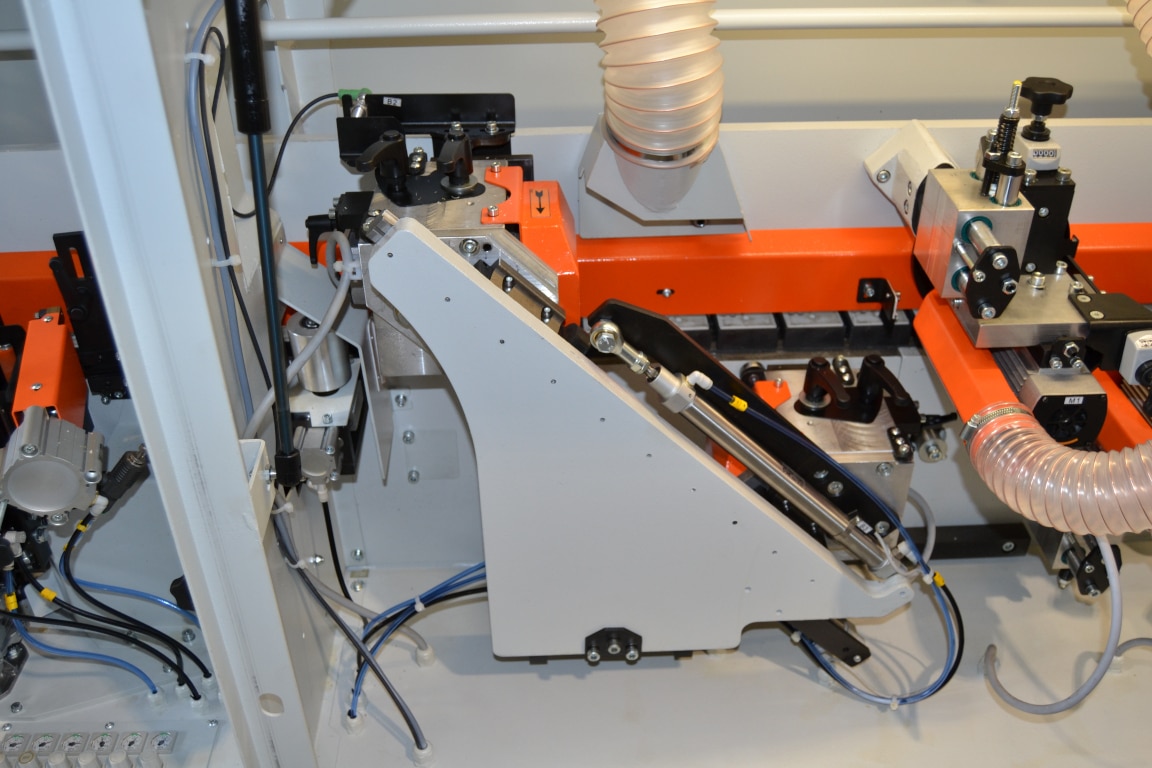

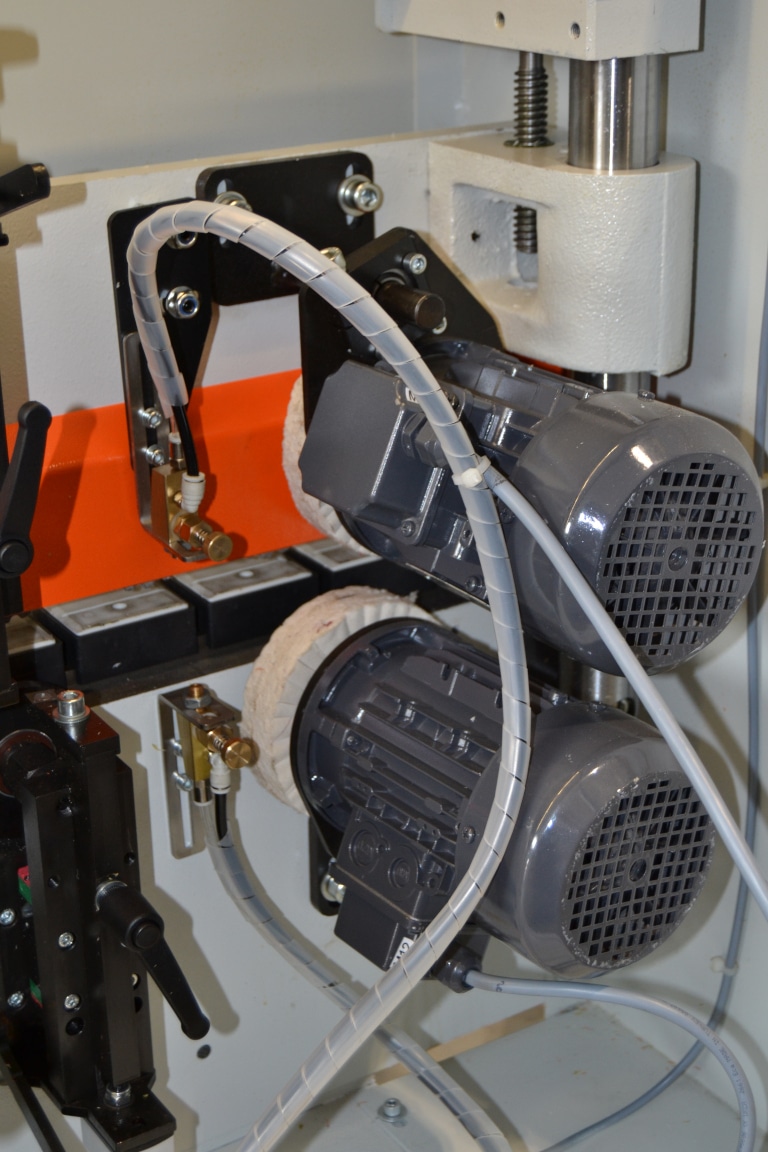

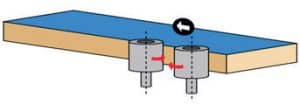

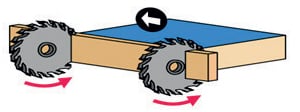

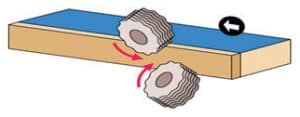

- Pre-milling unit

- 2 HF motors 12.000 rpm – kW 1,5 each

- 2 cutters ø 50

- useful working height 60 mm

- two HF motors featuring automatic timed operation to avoid panel chipping

- 1st motor anti-clockwise rotation / 2nd motor clockwise rotation

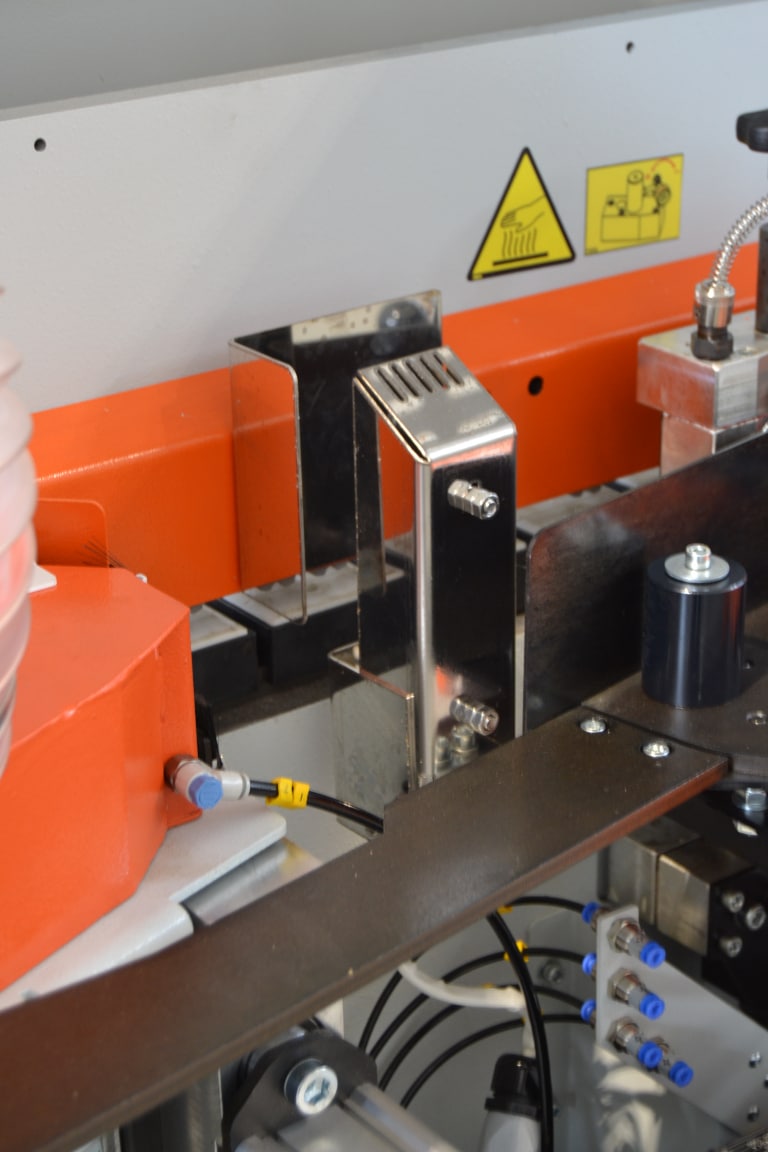

- IR lamp

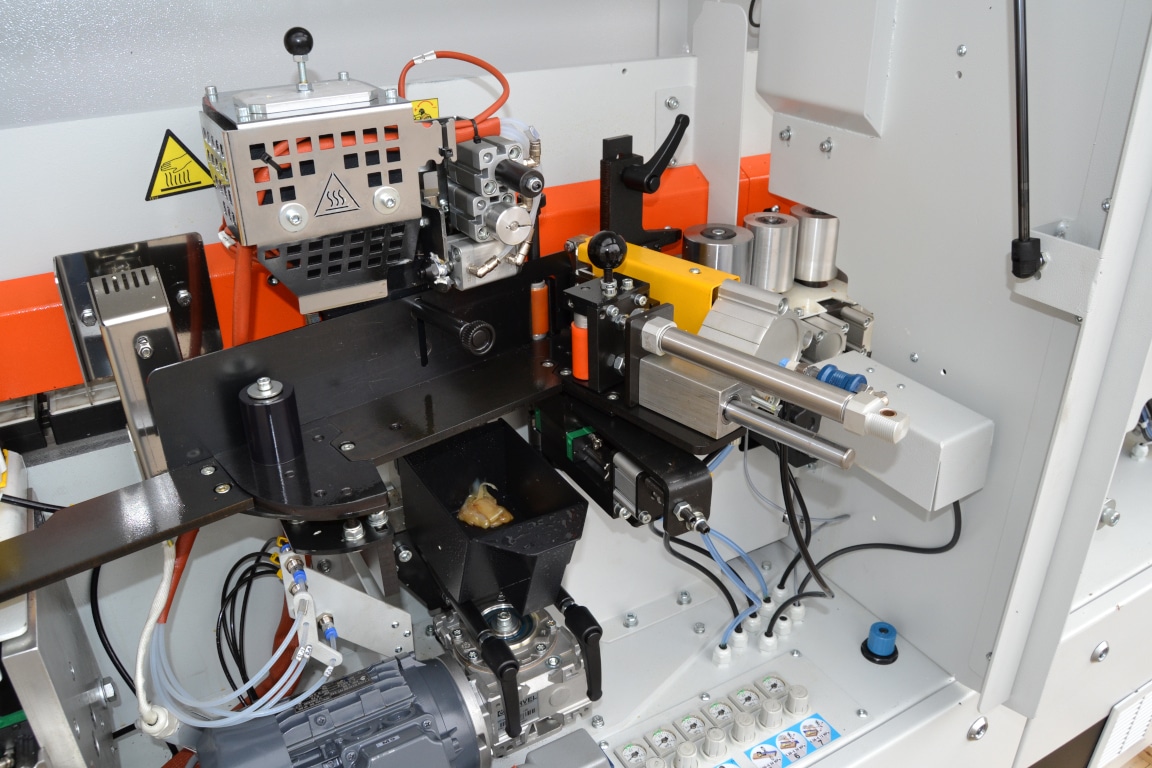

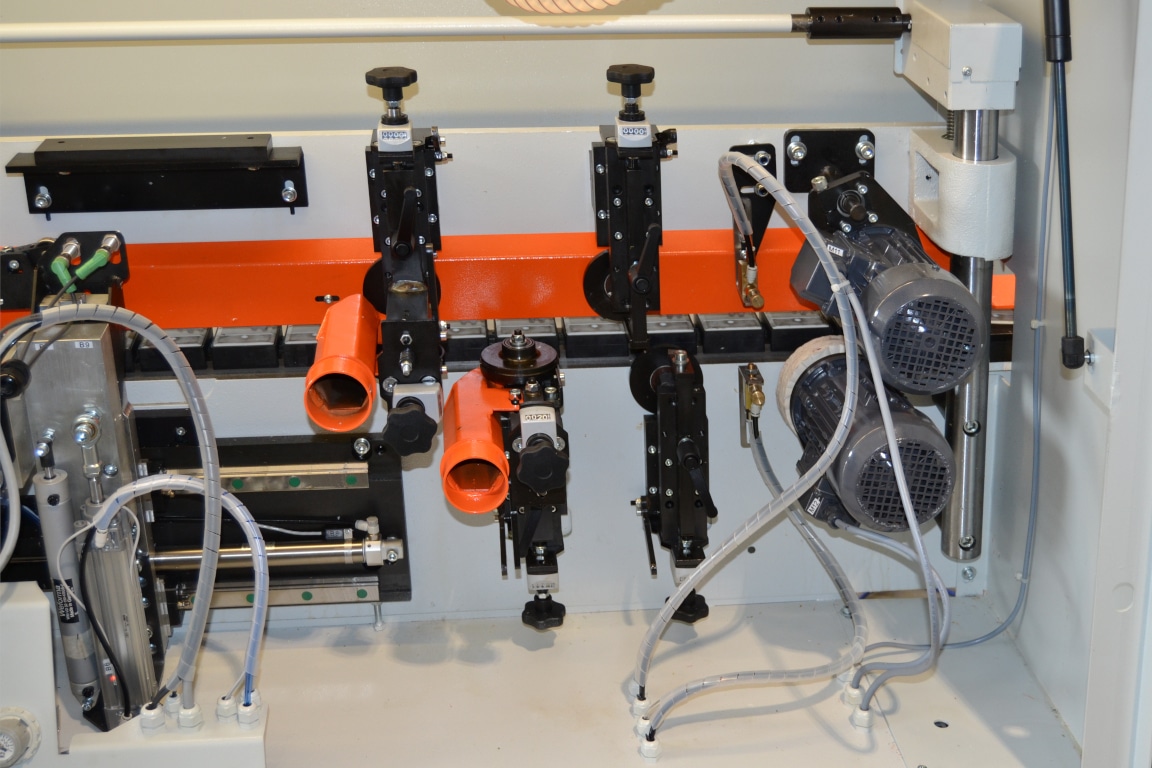

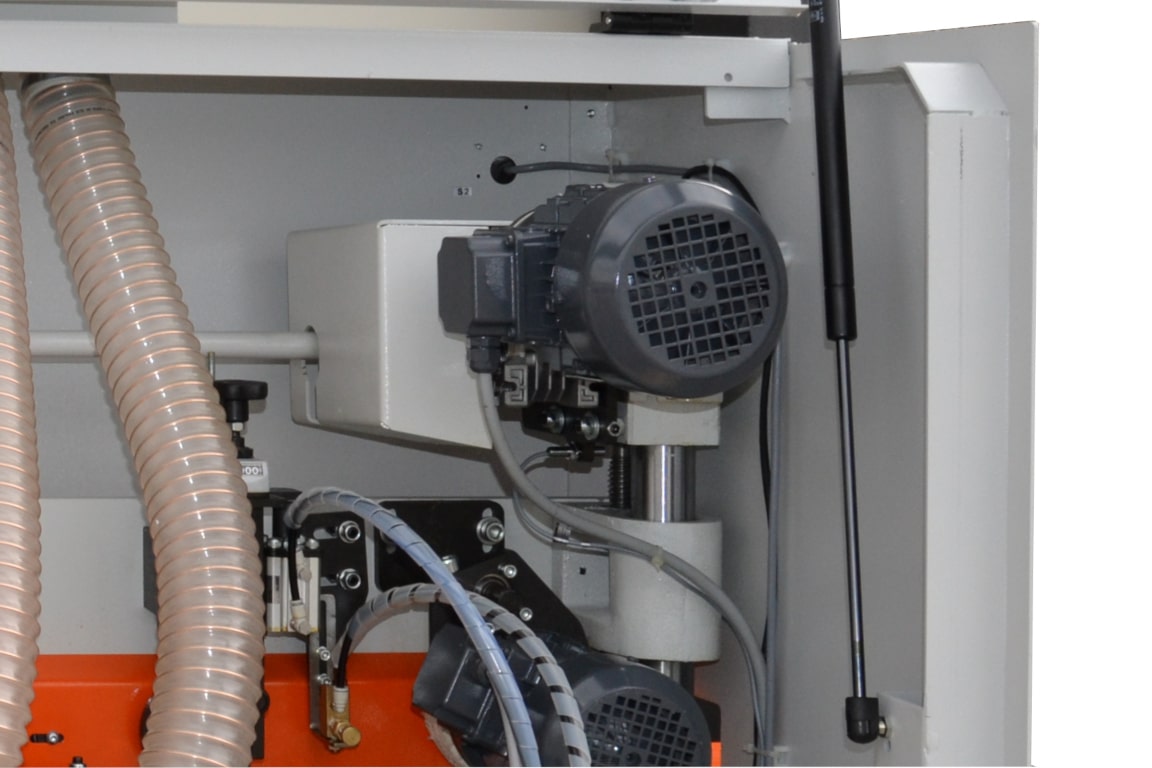

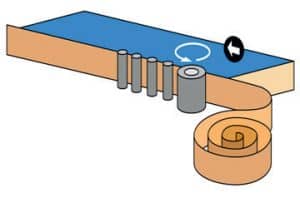

- Gluing unit

- Teflon pot / Glue spreading roller

- Temperature controlled through the control panel

- Glue pot with automatic stand-by of the temperature

- Edge pressure unit powered positioning managed by CN

- Nr. 1 rubbed pressure roller ø 70 mm ,2°,3° roller ø 55 mm

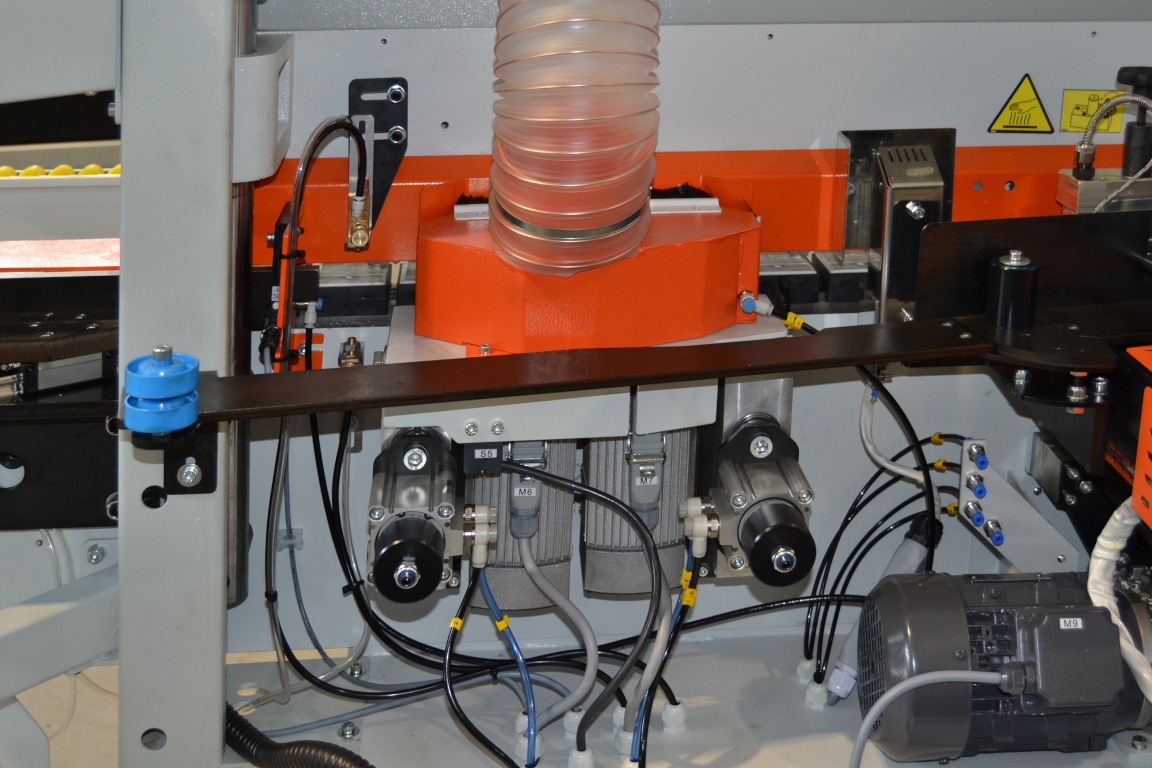

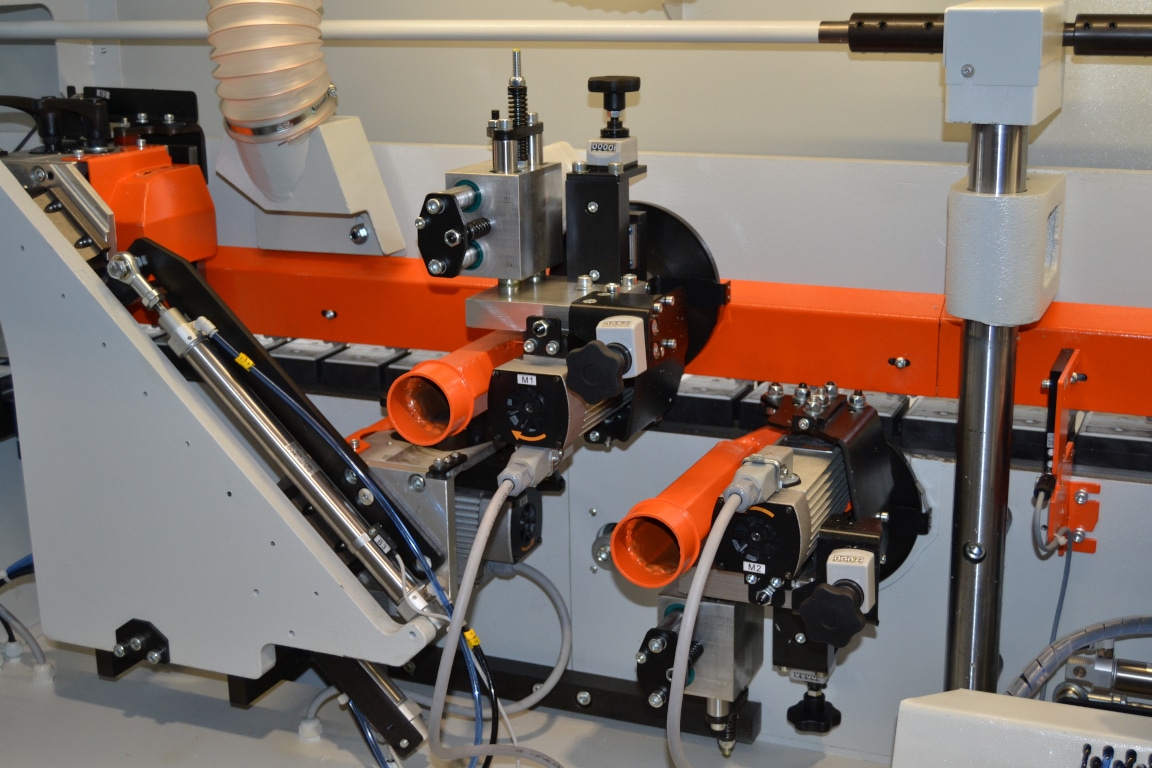

- End-Cutting unit

- Nr. 2 HF tilting motors 12.000 rpm – kW 0,22 each

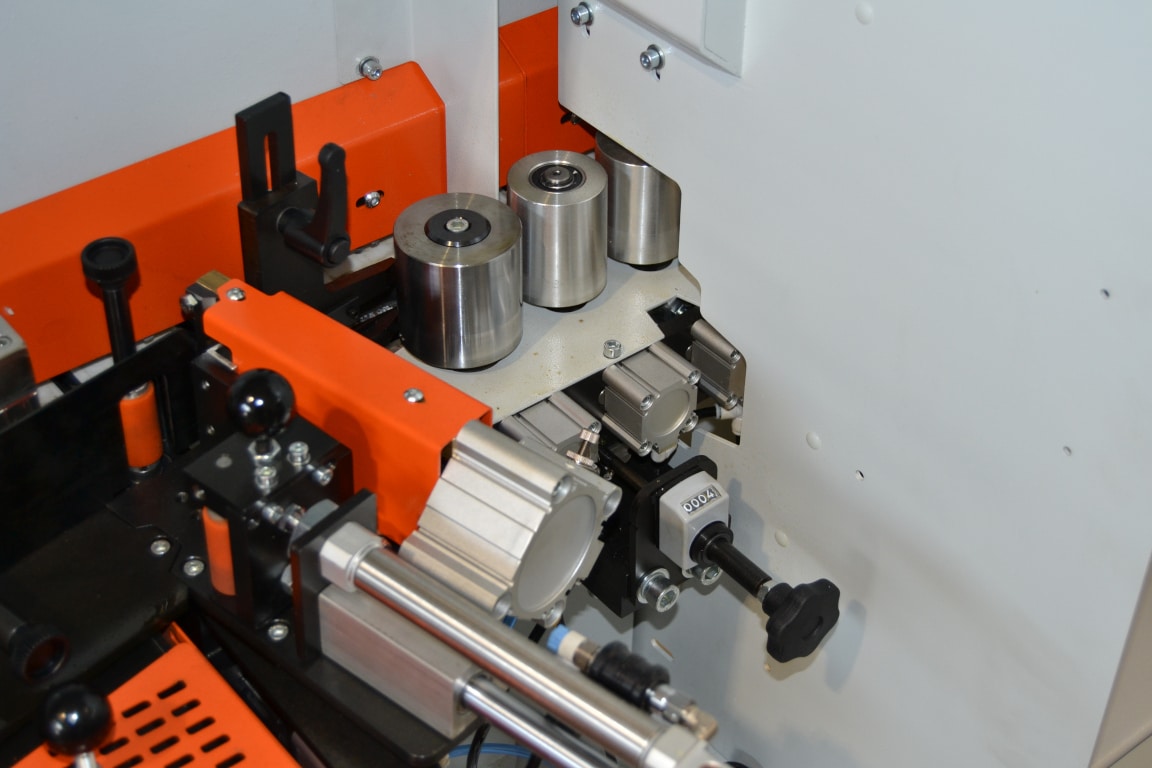

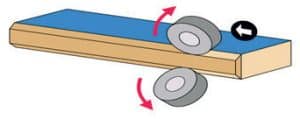

- Fine-Trimming unit powered positioning managed by CN

- 2 HF motors kW 0,55 each

- with digital readout

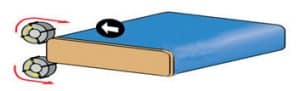

- Rounding unit powered positioning managed by CN

- 2 HF motors 12000 rpm – kW 0,55 each

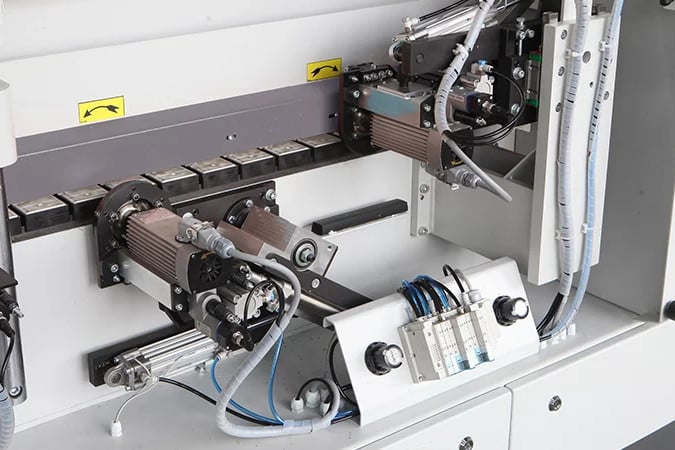

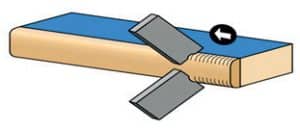

- Edge scraper unit powered positioning managed by CN

- Cleaning unit

- Glue scraper

- Brushes

UPON REQUEST

Request a quote

Request a personalized quote for your needs, we will contact you within 48 H!